الوصف

FOXBORO DCS PLC Modules

1. Product Name:

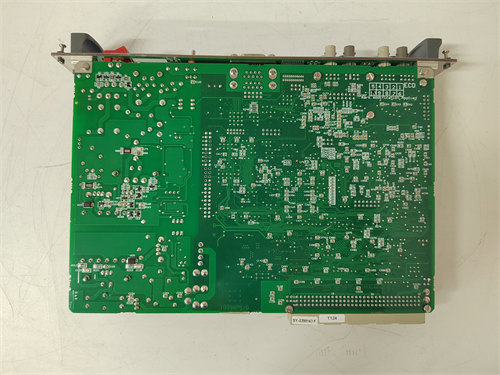

FOXBORO 0399143 SY-0301060R / SY-1025115C / SY-1025120E DCS PLC Modules

2. Product Description:

The FOXBORO 0399143 SY-0301060R / SY-1025115C / SY-1025120E modules are part of the FOXBORO I/A Series Distributed Control System (DCS), offering advanced solutions for process automation in a variety of industrial applications. These modules are designed for high reliability and performance in mission-critical control environments, such as oil & gas, power generation, chemical processing, refineries, water treatment, and pharmaceutical manufacturing.

These modules integrate seamlessly into the FOXBORO I/A Series DCS system, providing real-time control, monitoring, and diagnostics. The modules support a wide range of input/output (I/O) types, including analog, digital, and discrete signals, enabling flexible and scalable solutions for complex process control systems.

Each module in this series is engineered to offer high redundancy, scalability, and fault tolerance, ensuring that your system operates smoothly even in harsh, high-stakes industrial environments. These modules also support hot-swapping, which allows for maintenance and upgrades without interrupting system operations.

3. Product Parameters and Specifications:

Model Numbers:

- FOXBORO 0399143

- FOXBORO SY-0301060R

- FOXBORO SY-1025115C

- FOXBORO SY-1025120E

These models are part of the FOXBORO I/A Series, a family of distributed control system (DCS) products designed for real-time process automation in critical industries.

General Specifications:

- Manufacturer: FOXBORO (A division of Emerson Electric)

- Category: Distributed Control System (DCS) Modules

- Primary Use: Real-time process control, system monitoring, and integration within FOXBORO I/A Series DCS.

- Control System Compatibility: Compatible with FOXBORO I/A Series systems and other Emerson DeltaV DCS systems.

- Mounting: Typically rack-mounted or panel-mounted in standard control enclosures.

- Module Type: Analog Input/Output, Digital Input/Output, Discrete I/O, Communication.

Key Features and Capabilities:

-

Signal Processing:

- Analog I/O: Supports analog signal inputs (e.g., temperature, pressure, flow) and analog signal outputs for continuous control.

- Digital I/O: Manages digital signals such as on/off switches, alarms, and binary control signals.

- Discrete I/O: Handles discrete inputs/outputs, used for applications that require binary control.

-

Communication and Integration:

- Communication Protocols: Supports Modbus, Profibus, HART, and Ethernet/IP for inter-module and inter-system communication, allowing for flexible system integration and remote control.

- Real-time Data Communication: Allows high-speed, real-time data exchange across networked devices and systems, ensuring minimal delay for mission-critical process monitoring and control.

- Redundant Communication Paths: Redundancy features for communication ensure high availability and prevent data loss during network failures.

-

Redundancy and Fault Tolerance:

- Hot-Swappable Design: Supports hot-swapping of modules without system shutdown, reducing downtime during maintenance or upgrades.

- Fault-Tolerant Operation: The system is designed to handle failures and continue operating, ensuring process reliability in industrial applications.

- Redundant Power Supply: Many of these modules include redundant power supply support to avoid single points of failure and provide uninterrupted operation.

-

Scalability and Flexibility:

- Modular Architecture: The FOXBORO DCS modules support scalability, allowing users to expand their systems by adding more modules as their needs grow.

- Configurable I/O: The modules support configurable I/O points, enabling users to tailor the system to specific application requirements, whether they are digital, analog, or discrete.

- Flexible Configuration: Able to interface with a variety of field devices, including sensors, actuators, and controllers, providing a versatile solution for industrial automation.

-

Environmental and Mechanical Specifications:

- Operating Temperature: Typically supports an operating temperature range of 0°C to 60°C (varies by module).

- Shock and Vibration Resistance: Designed to withstand harsh industrial environments with moderate shock and vibration.

- Humidity Resistance: These modules can function in environments with moderate humidity, ensuring long-lasting operation in various industrial settings.

- EMC Compliance: Designed to meet Electromagnetic Compatibility (EMC) standards, preventing interference with other electronic devices.

-

Safety and Compliance:

- Safety Standards: Meets international safety standards such as CE, UL, and RoHS compliance.

- Intrinsic Safety: Some versions of these modules may support intrinsic safety for applications in hazardous areas, particularly in oil and gas or chemical plants.

- Explosion-Proof Compliance: Certain modules are designed to comply with explosion-proof standards for hazardous environments.

-

Power Specifications:

- Power Supply: Typically operates on 24 VDC power input (common for DCS systems).

- Power Consumption: Varies depending on module configuration but typically ranges from 10 to 20 Watts per module.

4. Applications:

The FOXBORO 0399143 SY-0301060R / SY-1025115C / SY-1025120E DCS modules are used in various industries requiring precise and reliable process control, such as:

-

Oil & Gas:

- Used for controlling pumps, compressors, valves, and safety shutdown systems in offshore platforms, oil refineries, and natural gas facilities.

-

Power Generation:

- Used in nuclear, coal-fired, gas-powered, and renewable energy plants for managing power generation processes and optimizing the operation of turbines, boilers, and electrical systems.

-

Chemical Processing:

- Applied in chemical production environments for controlling reactors, mixers, filtration systems, and chemical dosing processes.

-

Water and Wastewater Treatment:

- Utilized for monitoring water quality, managing pumping systems, filtration, and chemical treatments in municipal water treatment plants.

-

Pharmaceuticals:

- Deployed in pharmaceutical manufacturing processes, especially for applications requiring high precision in environmental control and product quality monitoring.

-

Manufacturing and Automation:

- Provides real-time control and monitoring in automated manufacturing environments, where precise control of machinery, robotics, and material handling is essential.

5. Conclusion:

The FOXBORO 0399143 SY-0301060R / SY-1025115C / SY-1025120E DCS PLC Modules offer robust and scalable solutions for critical process control applications. With features like redundant communication, hot-swapping, and high reliability, these modules ensure that industrial operations run smoothly even in the most demanding environments. Whether used in oil and gas, chemical, power generation, or manufacturing, they provide flexible, modular control that integrates well with existing systems, offering excellent support for modern industrial automation.

E1-202-00-000

KJ3222X1-BA1

HD22020-3

FXM5 10A-20A

EMERSON VE4036P2

VE4006P2 EMERSON

EMERSON VE4050S2K1C1

EMERSON VE4050S2K1C0

EMERSON VE4035S2B1

EMERSON VE4033S2B1

EMERSON VE4032S1T2B1

EMERSON VE4031S2T2B1

EMERSON VE5008

142U2E300BBCAA165240

DH7201X1-A4

EMERSON CL7652X1-A2

CL7001X1-AG

31B6459X012

EMERSON KJ4001X1-CA1/12P0623X042

EMERSON KJ3003X1-EA1/12P0921X022

EMERSON KJ4001X1-BB1/12P0619X032

ASEA BROWN BOVERI 511-CCZJ

ASEA BROWN BOVERI AF261SB2-2S3

ASEA BROWN BOVERI AFN01N2-AQS

ASEA BROWN BOVERI AFN312-EED

ASEA BROWN BOVERI XT1SU3110AAABAHXXX

ASEA BROWN BOVERI XT1SU3125AAABAHXXX

ASEA BROWN BOVERI AFN001F1-AJ1J

ASEA BROWN BOVERI T2H100BL

ASEA BROWN BOVERI AFN01X-HPD

ASEA BROWN BOVERI AFN01X-GND

ASEA BROWN BOVERI AFN001X-GHD

ASEA BROWN BOVERI T6H600TWA3AUS8

ASEA BROWN BOVERI T6H600TWA3S7

ASEA BROWN BOVERI 22F2-GP1

ASEA BROWN BOVERI 41M4-CR4

ASEA BROWN BOVERI A95M-30-22-84

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922