الوصف

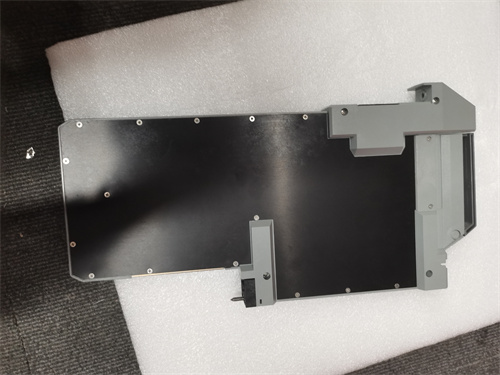

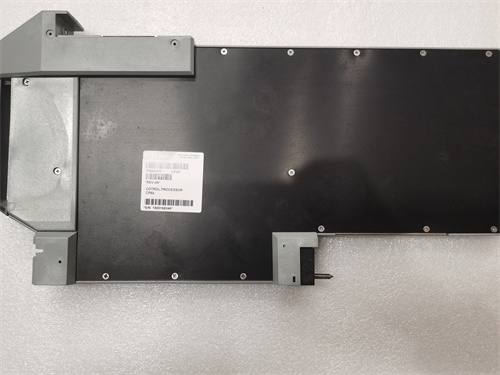

FOXBORO CP60 DCS/PLC Module

The FOXBORO CP60 is part of Emerson’s industrial automation system, used in Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) applications. The CP60 is designed to provide high performance and reliable control for complex industrial processes in sectors such as power generation, oil and gas, chemical processing, and water treatment. It is integrated into the Foxboro I/A Series control system, offering real-time control, diagnostics, and system management.

Product Name:

FOXBORO CP60 DCS/PLC Module

Product Description:

The FOXBORO CP60 is a highly reliable and scalable control processor module designed for Foxboro I/A Series Distributed Control Systems (DCS). It is engineered to handle complex automation tasks with flexibility and precision, serving as the core processing unit in a wide range of industrial applications. The module offers integration with both DCS and PLC functionalities, providing advanced real-time control, diagnostics, and communication for critical operations.

The CP60 module supports high-speed data processing, providing seamless control over automation systems, and can be easily integrated with existing systems. It includes multiple communication protocols, advanced diagnostic tools, and built-in redundancy features for fault tolerance and system reliability. This ensures that critical operations in industries like power plants, chemical processing, and manufacturing are maintained with minimal downtime.

Key Features:

-

Real-Time Processing:

- Ensures real-time data acquisition and control for critical processes, reducing latency and ensuring fast responses to changing conditions.

-

Dual-Processor Architecture:

- Built with dual processors to improve processing speed and provide redundancy, ensuring continuous operation even if one processor fails.

-

I/O Expansion:

- Supports a wide range of I/O modules, including analog, digital, and special-purpose I/Os, offering flexibility in system configuration and expansion.

-

Advanced Diagnostics:

- Features extensive self-diagnostics for continuous health monitoring of both the processor and connected I/O devices, providing early warnings and minimizing system downtime.

-

Built-in Redundancy:

- Redundant power supplies, communication paths, and processing capabilities to ensure high availability, making it ideal for critical applications where downtime is costly.

-

Integrated Communication:

- Supports Ethernet, Modbus, HART, and Profibus communication protocols, allowing seamless integration with SCADA systems, field devices, and other PLCs.

-

Modular Design:

- Flexible and scalable modular architecture, allowing the CP60 to be tailored to specific application needs and easily integrated into existing systems.

-

Safety Features:

- Includes built-in fail-safe mechanisms, such as automatic system shutdown in case of a fault, ensuring the safety of both personnel and equipment.

-

Program Flexibility:

- Supports different programming languages including Ladder Logic, Function Block Diagram, and Structured Text, offering versatility in developing control strategies.

Product Parameters and Specifications:

Electrical and Power Requirements:

- Operating Voltage: 24V DC (nominal).

- Power Consumption: Typically 20W – 50W, depending on configuration.

- Redundant Power Supply: Supports dual power supplies for fault tolerance, ensuring system reliability in case of power failure.

I/O Configuration:

- Analog Inputs: Can handle a variety of input types, such as 4-20mA and 0-10V signals, from field devices like sensors and transmitters.

- Digital Inputs/Outputs: Supports discrete signals, such as on/off states, for controlling devices like valves, motors, and alarms.

- Relay Outputs: Used to control high-power devices like motors, pumps, and alarms.

- High-Speed I/O: Includes high-speed pulse inputs/outputs for precise control in applications like turbine control or batch processing.

Communication Protocols:

- Ethernet/IP: For high-speed, Ethernet-based communication with SCADA systems, other PLCs, and HMI (Human-Machine Interface) devices.

- Modbus RTU/TCP: For communication with various field devices and external systems.

- Profibus DP: For integration with field devices in process automation, including sensors, actuators, and motor controllers.

- HART: Supports HART protocol for advanced process control and diagnostics.

- Redundant Communication Ports: Dual communication ports for enhanced network reliability.

Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Relative Humidity: Operates within 5% to 95% relative humidity (non-condensing).

- Vibration and Shock Resistance: Designed to meet industrial vibration and shock resistance standards to ensure reliability in harsh conditions.

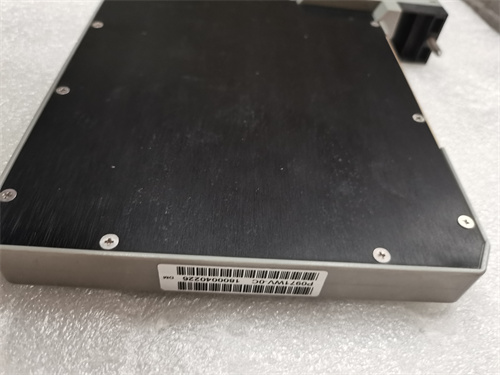

Physical Specifications:

- Dimensions: Rack-mountable, typically around 19″ width and 3U height (standard for industrial modules).

- Weight: Approximately 2.5 kg – 5 kg, depending on the configuration and I/O modules used.

Diagnostics and Maintenance:

- Self-Diagnostics: Built-in diagnostic tools for monitoring the status of the processor, I/O devices, and communication channels.

- Event Logging: Detailed logging of system events, alarms, and faults to aid in troubleshooting and system analysis.

- Alarm Reporting: Provides real-time alerts to operators for immediate action on system faults or performance degradation.

Programming and Configuration:

- Programming Languages: Supports Ladder Logic, Structured Text, and Function Block Diagram programming, enabling flexible control strategies.

- Development Environment: Configuration and programming can be done using Foxboro’s I/A Series Software or other third-party automation tools.

- Software Tools: FoxView, I/A Series Control Software, or other tools for system configuration, monitoring, and diagnostics.

Safety and Protection:

- Emergency Shutdown: Built-in safety features for automatic shutdown or failover in the event of critical failures.

- Redundant Systems: Redundancy built into critical systems like power supplies, communication, and processor units for continuous operation.

- Overload Protection: Built-in protections for electrical and communication overloads.

Applications:

-

Power Generation:

- Used for turbine control, generator monitoring, and overall plant control in power plants, ensuring efficient and reliable energy production.

-

Oil and Gas:

- Provides automation for upstream and downstream operations, including drilling, refining, and pipeline monitoring.

-

Chemical Processing:

- Used for controlling complex chemical processes, such as batch processing, reaction vessels, and distillation columns.

-

Water Treatment:

- Ideal for automation and control in municipal water systems, including chemical dosing, flow control, and pump regulation.

-

Manufacturing:

- Applied in automated production lines, quality control, and inventory management to improve efficiency and reduce downtime.

Conclusion:

The FOXBORO CP60 DCS/PLC Module is a robust and reliable controller module designed for distributed control systems in a wide range of industries. With its dual-processor architecture, advanced diagnostics, I/O flexibility, and built-in redundancy, the CP60 ensures high availability and fault tolerance in critical applications. Whether it’s used in power generation, oil and gas, chemical processing, or water treatment, the CP60 provides real-time control and seamless integration, making it an ideal solution for complex industrial automation systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922