الوصف

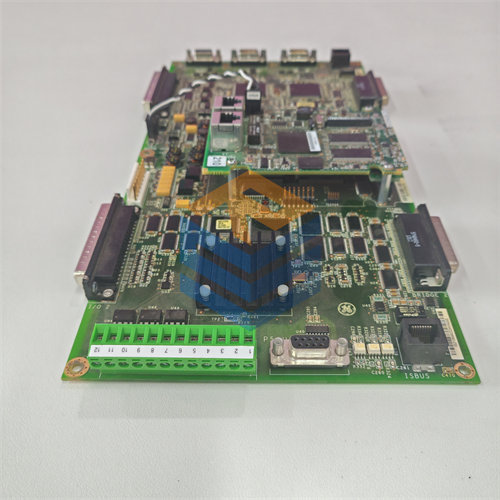

Product Description of GE 151X1215BD01WH05

GE 151X1215BD01WH05 is a high-performance printed circuit board (PCB) specifically designed for industrial automation and control systems. It is usually used as a core module in large-scale control systems such as programmable logic controllers (PLCS) or distributed control systems (DCS), mainly for processing and transmitting critical data.

Although the specific functions may vary depending on the system they are in, such modules typically act as communication interfaces, data processing units or signal processing boards to ensure efficient and reliable data exchange among the various components of the system.

Main features and advantages

Robust reliability: Specifically designed for harsh industrial environments, it can withstand temperature fluctuations, vibrations and electromagnetic interference, ensuring stable operation in critical applications.

High performance: It features rapid data processing capabilities and enables low-latency real-time communication between systems, which is crucial for industrial control applications that require immediate response.

Modular design: It adopts standardized interfaces and packaging, facilitating quick installation and replacement, and minimizing the time required for system maintenance and troubleshooting.

Compatibility: Perfectly integrated into GE’s ecosystem, ensuring seamless collaboration with other GE devices (for example, Multilin UR series protection relays).

Potential application fields

In the power industry: It is used in substations and power plants to monitor and protect the status of key equipment such as switch cabinets and circuit breakers.

Oil and gas: On drilling platforms or refineries, it may be used to collect and process real-time data from pressure and temperature sensors.

Water treatment: In water treatment plants, it is used to control the operation of pumps and valves to ensure the smooth flow of water and the chemical treatment process.

Manufacturing: On automated production lines, as part of the control system, it coordinates the operation of different machines and sensors.

Technical Specifications (Tentative)

Parameter

Description

Product type

Printed circuit board (PCB) module

Compatibility series

GE Multilin UR series

Main functions

Protocol Bus communication interface

Supply voltage

24VDC (tentative)

Working temperature

-20°C to 60°C (tentative)

Signal type

Analog/digital signals (depending on the application)

Related products

To better understand the function of GE 151X1215BD01WH05, you can refer to industrial control modules with similar functions from other brands

Siemens Simatic S7-1500: Its I/O module series such as SM 521 offer similar data acquisition and processing capabilities within the Siemens ecosystem.

Rockwell Automation ControlLogix 1756-IB16: This is a digital input module that plays a role in collecting signals from field devices in Rockwell’s control systems.

ABB 3BSE042232R1: As part of the ABB DCS system, this I/O module offers connection and communication capabilities similar to those of GE products.

Bently Nevada 3500/05: Although it focuses more on mechanical vibration monitoring, its I/O module is similar to that of GE 151X1215BD01WH05, both playing a role in collecting and processing key data within their respective system frameworks.

Honeywell FSC-3000: This system is renowned for its highly reliable safety control, and its I/O modules also offer the ability to handle critical process data, but the focus is on safety features.

Summary

The GE 151X1215BD01WH05 is a dedicated PCB module designed for industrial control systems. With its robust design and efficient communication capabilities, it ensures the reliable operation of critical processes and data transmission.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922