الوصف

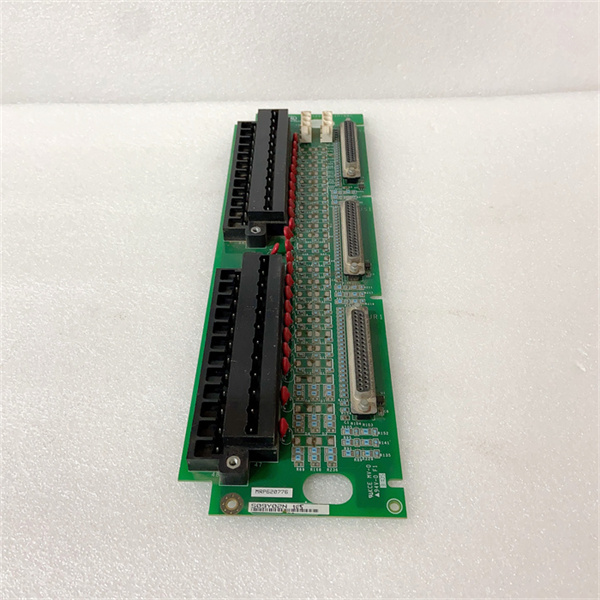

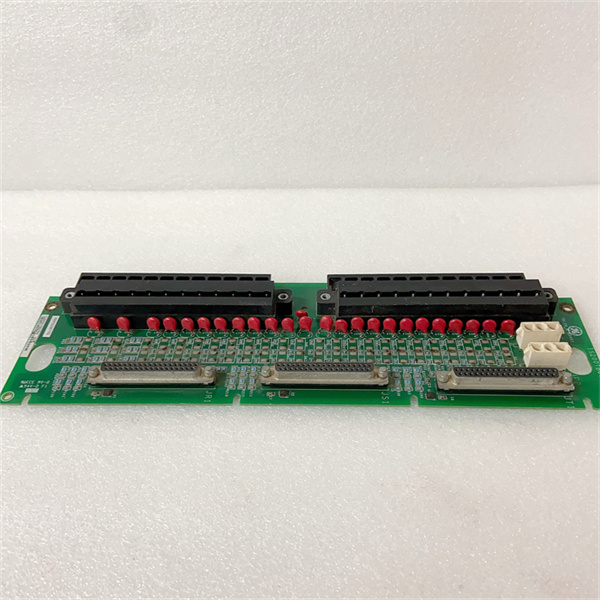

The GE DS200ACNAG1ABB ARCNET Board is a specialized component used in the GE Mark V turbine control system. It plays a critical role in enabling communication within the control system, particularly in environments where real-time data exchange is essential for managing turbine operations.

Key Features of the DS200ACNAG1ABB:

- ARCNET Communication Protocol: The board uses the ARCNET protocol for data transmission, a reliable method that utilizes token-passing for managing network traffic and reducing collisions.

- Integration with Mark V System: The DS200ACNAG1ABB is specifically designed for seamless compatibility with the Mark V turbine control system, ensuring reliable communication between multiple controllers, sensors, and actuators.

- High-Speed Data Transfer: This ARCNET board supports high-speed communication, facilitating real-time data acquisition and control necessary for optimal turbine performance.

- Robust Diagnostics: The board is equipped with diagnostic capabilities that help identify network status and issues, allowing for timely maintenance and minimizing downtime.

- Durable Design: Constructed to endure harsh industrial conditions, the DS200ACNAG1ABB is designed to provide longevity and reliability in demanding environments.

Applications:

- Turbine Control Systems: Primarily utilized within the Mark V turbine control system, the board ensures effective communication between various control components that manage turbine operations.

- Real-Time Monitoring: It plays a vital role in monitoring turbine performance, collecting essential operational data, and enabling feedback loops for controlling turbine functionalities.

- Interconnected Device Communication: The board allows for communication between different subsystem components, such as I/O devices, HMIs, and controllers, enhancing the overall reliability of the automation system.

Installation and Configuration:

- Mounting: Follow specific GE guidelines to mount the DS200ACNAG1ABB securely within the control cabinet, keeping in mind the need for proper ventilation.

- Wiring: Connect the board to the ARCNET network and other system components using appropriate cabling and connectors to ensure signal integrity.

- Software Configuration: After installation, configure the board using appropriate software tools, setting communication parameters for optimal interoperability with other devices in the system.

Maintenance:

- Routine Diagnostics: Regularly engage in diagnostic checks using the board’s built-in features to ensure the integrity and performance of the communication network.

- Visual Inspection: Perform periodic visual inspections of the card and associated wiring to identify any signs of wear, damage, or loose connections.

- Firmware Updates: Keep the board’s firmware updated according to GE’s recommendations to ensure it benefits from the latest functionality and security patches.

If you have specific inquiries about the DS200ACNAG1ABB ARCNET Board, such as detailed technical specifications, troubleshooting procedures, or specific operational scenarios, please feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922