الوصف

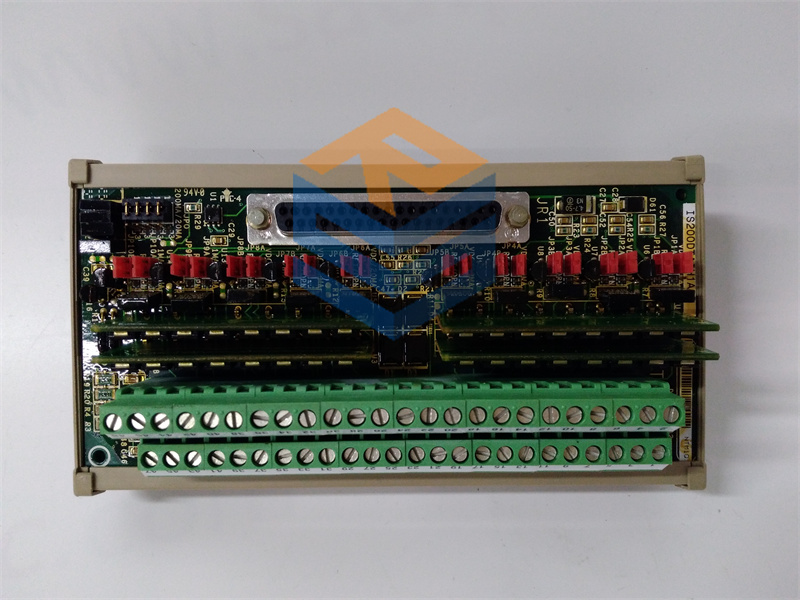

The GE DS200CVMAG3AEB Cap/Fuse Voltage Monitor Board is a specialized component within the GE Mark VI control system, which is widely used in industrial applications, particularly for gas and steam turbines. This board is crucial for monitoring capacitor voltages and the status of fuses in excitation systems, ensuring the safe and reliable operation of generators.

Key Features:

- Capacitor Voltage Monitoring: The DS200CVMAG3AEB continuously monitors the voltage levels across capacitors. By tracking these levels, it helps maintain optimal performance of the excitation system, which is essential for the stability of electrical power output.

- Fuse Status Monitoring: The board also monitors the status of fuses associated with the excitation system. It can detect blown fuses and trigger alarms, providing early warnings that can prevent potential system failures.

- Analog Signal Processing: The assembly includes circuitry for effective analog signal processing. This ensures the accuracy and reliability of the voltage readings communicated to the control system.

- Alarm and Diagnostic Functions: The DS200CVMAG3AEB is designed to issue alarms when abnormal conditions arise, such as unexpected voltage levels or fuse failures. This feature enhances operational safety and allows for prompt corrective actions.

Applications:

- Generator Excitation Systems: The board is essential for managing generator excitation, helping to ensure that voltage remains steady and within acceptable limits.

- Turbine Control Integrations: Integrated into turbine control systems, the assembly enhances overall operational efficiency by providing critical voltage feedback and ensuring the system responds effectively to changing conditions.

Maintenance Considerations:

- Routine Inspection: Regular inspections are recommended to check for physical damage, corrosion, or loose connections, which could impair the board’s functionality.

- Utilization of Diagnostics: Make use of the built-in diagnostic tools to assess the operational status of the board and troubleshoot any issues that may arise.

- Refer to Technical Documentation: For detailed information regarding installation, configuration, and troubleshooting protocols, refer to the official GE technical manuals associated with the Mark VI control system.

Conclusion:

The GE DS200CVMAG3AEB Cap/Fuse Voltage Monitor Board is an integral part of ensuring reliable and safe turbine operation within the GE Mark VI control system. Its ability to monitor critical voltage levels and fuse conditions helps prevent failures and enhances the overall performance of generator systems. For more specific guidance or technical support, it is advisable to consult GE technical documents or engage qualified service personnel familiar with the system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922