الوصف

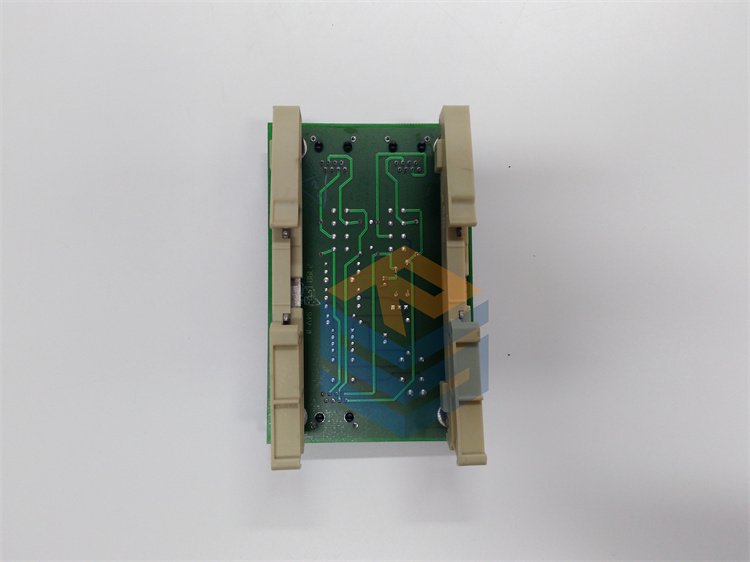

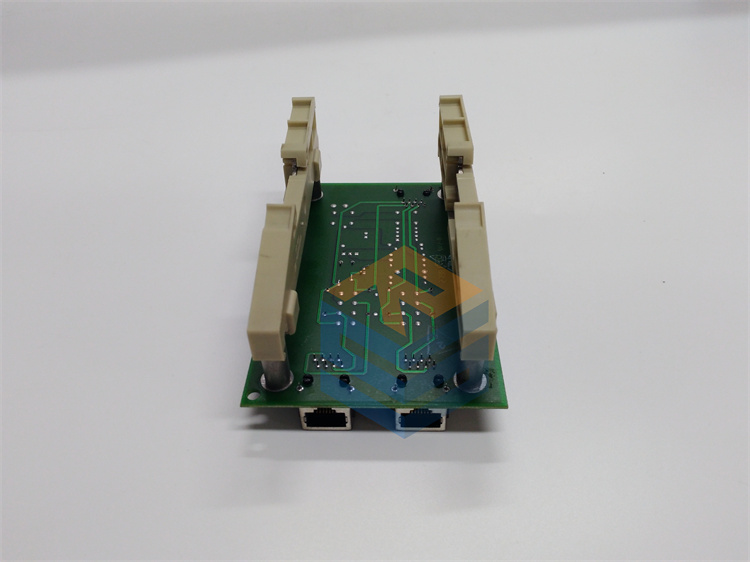

The GE DS200DCFBG1 Power Supply Board is a critical component in the GE Mark VI control system, effectively utilized in industrial applications, particularly in gas and steam turbine control systems. This power supply board is designed to provide essential power management and distribution for various components within the control system.

Key Features:

- Power Regulation: The DS200DCFBG1 is responsible for converting and regulating input power to supply the appropriate DC voltages required for the operation of control system components.

- Multiple Output Voltages: This power supply board typically provides several different output voltages, making it versatile for powering various elements within the control architecture, such as processors, communication modules, and drive control cards.

- Protection Circuits: The board includes integrated protection mechanisms to defend against over-voltage, under-voltage, and over-current conditions, thereby enhancing the reliability and longevity of the system.

- Diagnostics Capability: The DS200DCFBG1 features onboard diagnostics that provide real-time monitoring of power supply status, helping to identify potential issues and enabling proactive maintenance.

- Compatibility: This board is designed to integrate seamlessly with other components of the GE Mark VI system, ensuring a cohesive functionality across the control system.

Applications:

- Turbine Control Systems: The primary application of the DS200DCFBG1 Power Supply Board is in turbine control systems, where it supplies vital power to the various control and monitoring components.

- Industrial Automation: It can also be utilized in other industrial automation systems where reliable power supply and management are required.

Maintenance Considerations:

- Routine Checks: Regular inspections should be conducted to ensure the board is free from damage, contamination, or loose connections, which could affect performance.

- Utilization of Diagnostics: Operators are encouraged to leverage the diagnostic features for ongoing monitoring, assisting in the early detection of any abnormalities or potential failures.

- Reference Documentation: For detailed instructions regarding installation, configuration, troubleshooting, and maintenance, consulting the official GE technical manuals specific to the DS200DCFBG1 is essential.

Conclusion:

The GE DS200DCFBG1 Power Supply Board is a fundamental component within the GE Mark VI control system, providing essential power management for turbine operations and industrial applications. With its robust features, including voltage regulation, diagnostics, and protection mechanisms, it plays a vital role in ensuring system reliability and efficiency. For further assistance or information, it is advisable to consult GE documentation or engage with trained technical personnel.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922