الوصف

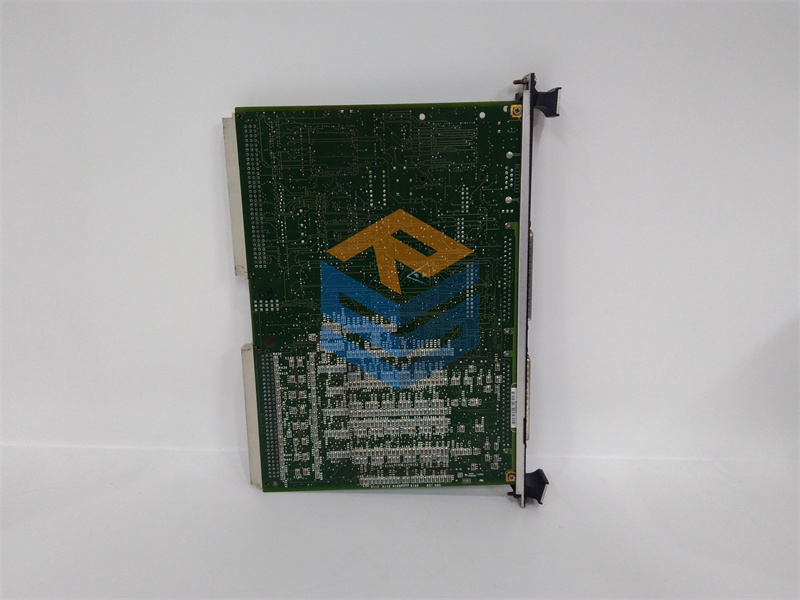

The GE DS200DCFBG1BJB Power Supply Board is a specific model within the GE Mark VI control system, which is widely used in industrial applications, particularly for the control and automation of gas and steam turbines. This board is essential for providing and regulating power supply needs across the system.

Key Features:

- Power Regulation: The DS200DCFBG1BJB is responsible for ensuring stable power delivery to various components of the control system. It regulates the input power to provide the necessary DC voltage for the operational requirements of the system.

- Monitoring and Feedback: This board collects and processes feedback on the power supply, allowing for real-time monitoring of performance. This feature helps in identifying any discrepancies in power levels that could affect system efficiency.

- Diagnostic Functions: It is equipped with built-in diagnostic capabilities that enable operators to monitor the board’s health. This helps in early detection of faults or failures, reducing potential unplanned downtime.

- Protection Circuits: The board includes various protection mechanisms designed to safeguard it against conditions such as over-voltage, over-current, and overheating. These features enhance the reliability of the power supply and protect other connected components.

- Seamless Integration: The DS200DCFBG1BJB is designed to work seamlessly with other components within the GE Mark VI control system, allowing for straightforward incorporation into existing setups.

Applications:

- Turbine Control: The primary application for this power supply board is in turbine control systems, where it plays a vital role in ensuring that the control electronics receive stable and appropriate power.

- Industrial Machinery: It may also be utilized in other sectors requiring reliable power supply and feedback systems as part of broader industrial automation solutions.

Maintenance Considerations:

- Routine Inspections: Regular checks should be conducted for any physical damage, loose connections, and general wear that could affect the board’s performance.

- Utilization of Diagnostics: Operators should regularly review diagnostic information to preemptively address issues before they can impact system performance.

- Consulting Documentation: It is advisable to refer to the official GE technical manuals for comprehensive information on installation, troubleshooting, and maintenance related to the DS200DCFBG1BJB.

Conclusion:

The GE DS200DCFBG1BJB Power Supply Board is a crucial component in the GE Mark VI control system, designed to provide reliable power management and feedback necessary for the efficient operation of turbine and industrial automation applications. Its diagnostic capabilities and protection features further enhance its reliability. For further information or technical support, referring to GE’s official documentation or consulting with qualified personnel is recommended.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922