الوصف

The GE DS200DENCF1BDD SOFTWARE PROM SET is a key component for GE’s Mark V Speedtronic series, a system designed to control gas and steam turbines. The PROM SET, which stands for Programmable Read-Only Memory, contains the core firmware and configuration data that dictate how the control system operates.

This component is essentially the “brain” of a specific control board, holding the software program that manages critical turbine functions like speed, temperature, and vibration. The specific alphanumeric code, like “BDD,” refers to a particular version of the software, and it’s essential to use the correct version for system compatibility.

Product Features and Function

The DS200DENCF1BDD SOFTWARE PROM SET is more than just a memory chip; it’s a vital part of the control loop. It ensures that the control system can:

- Store and Execute Firmware: The PROM set stores the executable code that tells the processor how to react to inputs from various sensors and how to send commands to output devices, like fuel valves and actuators.

- Ensure System Compatibility: The version number in the part code ensures that the software is compatible with the specific hardware revision of the control board. Mismatched versions can lead to communication errors or complete system failure.

- Provide Non-Volatile Memory: As a PROM, the memory is non-volatile, meaning it retains the program even when the power is turned off. This is crucial for maintaining the system’s core functionality and settings.

Related Components

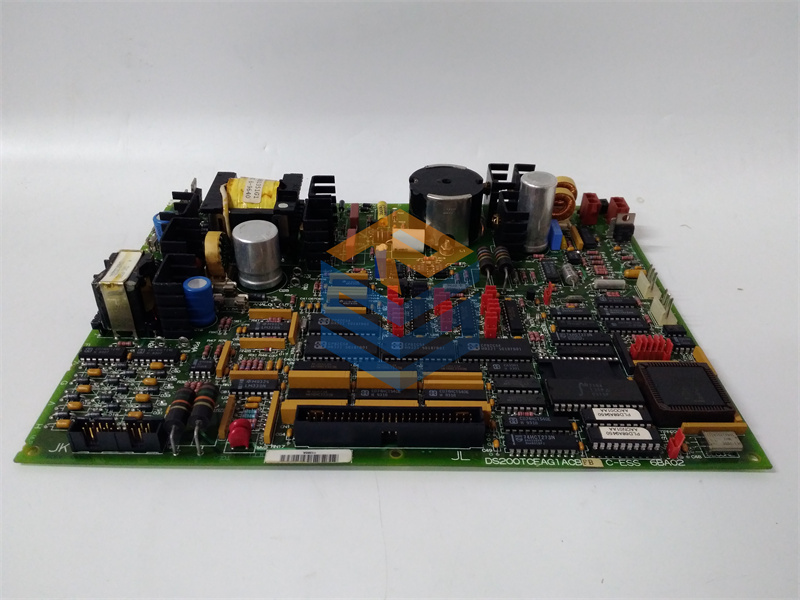

This PROM set does not operate alone; it’s a part of a larger, integrated system. It is typically installed on a main processor board, such as a DS200 series card, which is part of a larger control cabinet. Other related components include:

- I/O (Input/Output) Boards: These boards handle the signals coming from and going to the turbine’s sensors and actuators.

- Terminal Boards: These are the physical connection points for wiring from the field devices to the control system.

- Power Supplies: A dedicated power supply provides clean and stable power to all the electronic components within the control cabinet.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922