الوصف

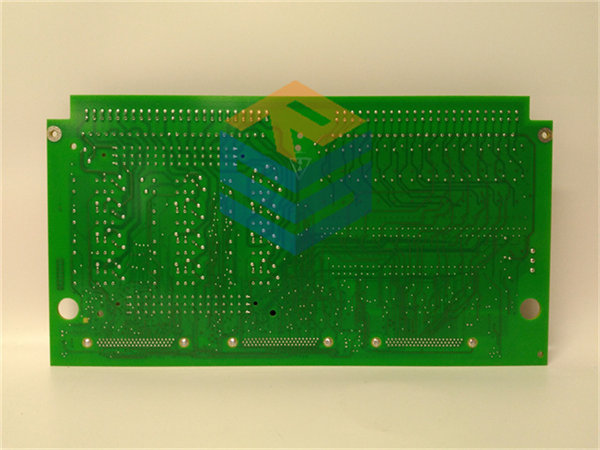

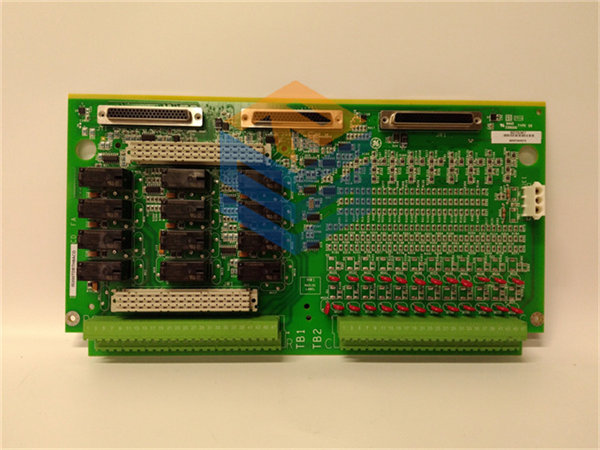

The GE DS200DMCAG1AGB is an integral part of GE’s Mark V control system, commonly used in gas and steam turbine applications. This particular board is known for its robust functionality in managing communication between various components within the turbine control system. Below is a detailed overview of the DS200DMCAG1AGB Gen/Log/Key Interface Board, including its features, specifications, and maintenance considerations.

Key Features:

- Communication Interface:

- The DS200DMCAG1AGB serves as an interface that facilitates communication between the central processing unit (CPU) and other peripheral devices. This is essential for data exchange necessary for system monitoring and control.

- General Purpose I/O:

- The board is equipped with multiple general-purpose input/output (GPIO) channels, allowing it to connect with various field devices, such as sensors and actuators.

- Diagnostic Capabilities:

- It includes built-in diagnostic features and LED indicators that provide real-time status updates regarding the board’s operational health and any faults.

- Modular Design:

- The modularity of the DS200DMCAG1AGB allows for easy replacement and maintenance, reducing downtime during servicing and enhancing reliability.

- Compatibility:

- Designed specifically to work seamlessly within the GE Mark V control architecture, ensuring compatibility with other system components.

Specifications:

- Power Requirements: Detailed specifications regarding voltage and current can be found in the manufacturer’s documentation; these should be adhered to in order to avoid operational issues.

- Operating Temperature Range: The board is designed to operate efficiently within specified temperature limits suitable for industrial environments.

- Physical Connections: The board features a variety of connectors for easy integration into the control system, facilitating straightforward installation and configuration.

Installation and Maintenance:

- Installation:

- Install the DS200DMCAG1AGB according to GE’s guidelines, ensuring that it is securely mounted and that all connections are properly made to prevent communication errors.

- Maintenance:

- Regular maintenance should include visual inspections and functionality checks. Monitor the board’s LED indicators for any signs of malfunction, and maintain proper connections and cleanliness.

- Firmware Updates: Keep the board’s firmware up to date by consulting GE’s resources to ensure optimal performance and security.

Troubleshooting Tips:

- LED Status Indicators:

- Utilize the onboard LED indicators to promptly diagnose operational statuses and any potential faults.

- Connection Checks:

- Verify that all wiring and connectors are intact and secure since loose connections can cause operational issues.

- Diagnostic Tools:

- Use GE’s diagnostic software tools to perform comprehensive assessments of the board and the overall control system.

- Refer to Documentation:

- For specific troubleshooting procedures, reference the official GE documentation associated with the DS200DMCAG1AGB board.

Documentation:

For detailed information, including installation instructions, wiring diagrams, operational guidelines, and technical specifications for the DS200DMCAG1AGB Gen/Log/Key Interface Board, it is essential to refer to the official GE documentation.

If you have any specific queries or require additional information about the DS200DMCAG1AGB board or its applications, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922