الوصف

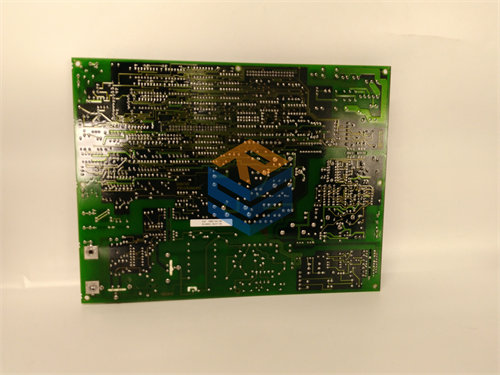

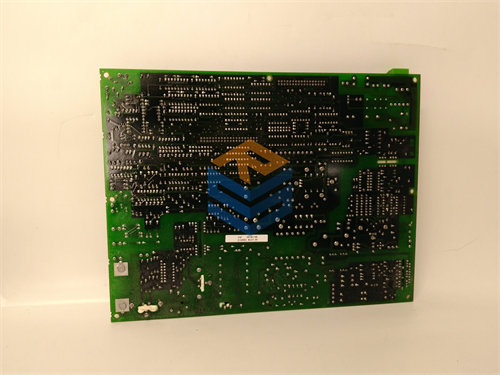

GE DS200DMCBG1AGD/RR Module

Brief Product Description

The GE DS200DMCBG1AGD/RR is a specialized industrial module designed for use in GE’s turbine control systems, such as the Speedtronic Mark V and Mark VI series. It functions as a dynamic control and data management unit, providing the processing and logic required for the stable, efficient, and safe operation of large gas or steam turbines.

Key Specifications:

- Type: Industrial Control Module

- Compatibility: GE Speedtronic Mark V & Mark VI turbine control systems

- Function: Dynamic control, data processing, and communication

- Application: Turbine control, power generation

Detailed Product Overview

In the high-stakes world of power generation, a turbine’s performance and safety hinge on its control system. The DS200DMCBG1AGD/RR is a crucial component in that system. Think of it as the brain of the turbine, handling complex, real-time calculations. It takes in a flood of data from various sensors—like temperature, pressure, and speed—and, in a fraction of a second, sends precise commands to actuators to adjust fuel flow and other critical parameters. This isn’t just about keeping the turbine running; it’s about optimizing its performance for peak efficiency and preventing catastrophic failures.

The “RR” in the part number often signifies that the module has been remanufactured. This makes it a cost-effective solution for facilities that need to maintain and service older, but still reliable, turbine control systems without investing in a complete system overhaul. The module’s robust construction ensures it can handle the tough conditions of a power plant, including high heat, vibrations, and electrical noise.

Technical Specifications

Key Features and Benefits

- Precision Control: The module provides the computing power and logic necessary for accurate and responsive turbine control, which is essential for managing power output and preventing damage.

- High Reliability: Built to GE’s rigorous industrial standards, this is a durable and dependable component, reducing the risk of unscheduled downtime.

- Cost-Effective Maintenance: As a remanufactured part, it provides a more affordable alternative to a brand-new module, helping to extend the operational life of legacy control systems.

Primary Applications

The GE DS200DMCBG1AGD/RR is almost exclusively used in the power generation industry. It is an integral part of the control systems for gas and steam turbines, ensuring they operate safely and efficiently. These systems are used in power plants, oil and gas facilities, and other large-scale industrial sites where the precise control of rotating machinery is paramount.

Related Products

When a system uses the GE DS200DMCBG1AGD/RR module, it is typically part of a larger control architecture. Other components in the same system might include:

- Bently Nevada 3500/65: A machine protection system that works alongside the turbine control system, providing an extra layer of safety by monitoring for vibration and other physical parameters.

- GE DS200TCIAG1A: A similar type of card or module from the same series that might handle different control or I/O functions.

- Rockwell ICS T8151B: A triple-redundant processor module used in safety systems, highlighting the industry’s focus on fail-safe designs, which is a key principle in turbine control as well.

- Emerson DeltaV I/O Modules: These modules serve a similar purpose, connecting a control system to field devices, demonstrating a common function across different automation platforms.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922