الوصف

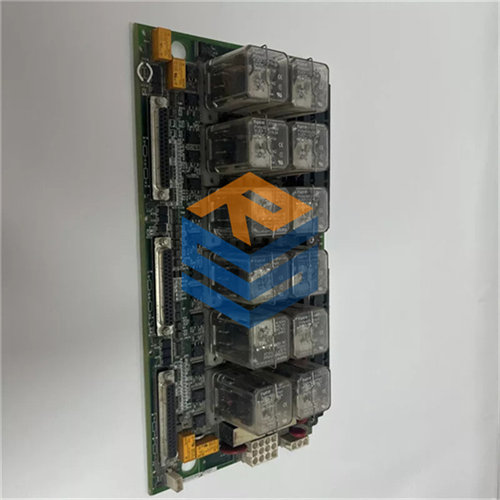

The GE DS200DTBCG1A is a specialized Digital Output Terminal Board for the Mark V series of turbine control systems. Its primary function is to provide a robust, reliable, and protected interface for controlling high-current inductive loads, such as relays and solenoids, directly from the control system.

Technical Breakdown ⚙️

The model number provides a clear breakdown of its function:

- DTBC (Digital Contact Terminal Board): This board is a type of digital I/O interface. The “C” in the designation often implies a specific application or feature. In this case, the board is designed to handle the unique electrical characteristics of inductive loads.

- Relay/Solenoid Control: This is the most critical feature. When a relay or solenoid is de-energized, its magnetic field collapses, generating a powerful high-voltage spike (back electromotive force or EMF). A standard digital output board could be damaged by this voltage. The DS200DTBCG1A is specifically engineered with built-in suppression circuitry (e.g., flyback diodes) to safely dissipate this back EMF, protecting the sensitive control electronics from damage and ensuring the longevity and reliability of the system.

- Terminal Board: This board provides the physical gateway for field wiring. It uses robust screw terminals and high-density connectors to allow direct connection of external devices, simplifying wiring and providing a standardized, easily accessible interface.

- MKV (Mark V): This board is a component of the GE Mark V Speedtronic turbine control system, known for its high reliability and triple-redundant architecture. The DS200DTBCG1A plays a vital role in providing the high-power digital outputs needed to control critical turbine auxiliaries.

In essence, this board is a purpose-built safety and reliability component, ensuring that the control system can safely and effectively actuate powerful devices in the field without risking damage to its own delicate internal electronics.

Applications 🏭

The GE DS200DTBCG1A is a critical component in the control systems of:

- Gas and Steam Turbines: It is used to actuate relays for motor control, solenoid valves for fluid or gas control, and other inductive loads essential for turbine startup, operation, and shutdown sequences.

- Power Plants: It is employed to control alarms, indicators, and other high-power digital outputs.

- Industrial Automation: It can be used in other industrial applications requiring a reliable and protected interface for controlling solenoids and relays.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922