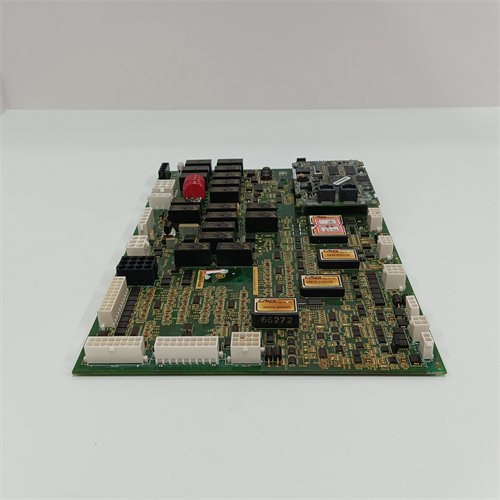

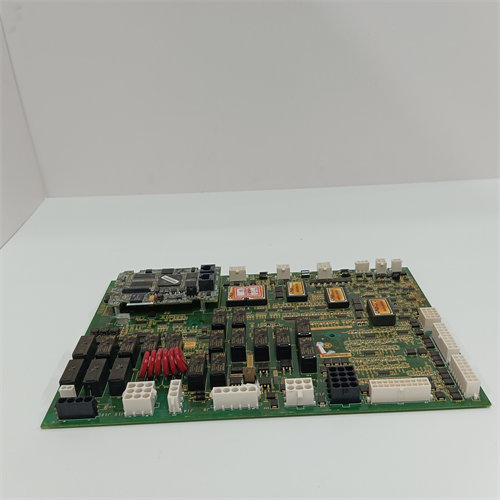

الوصف

The GE DS200FCSAG1A is a Current Sensing Interface Board used in GE’s turbine and drive control systems, including the Mark V Speedtronic and LS2100 Static Starter. This board is a critical feedback component that measures the current flowing through a circuit and converts that measurement into a signal the main control processor can use.

Technical Breakdown 🧠

The card’s function is foundational to the system’s control and protection schemes:

- Current Sensing: The board’s primary role is to measure the electrical current flowing through a specific part of the system, such as a motor, power bridge, or other load. It uses specialized components like current transformers to non-intrusively sense the current, providing a real-time, accurate reading without requiring a direct electrical connection to the high-power circuit.

- Feedback & Interface: The measured current is then converted into a usable analog or digital signal (e.g., a 4-20mA output). This signal is sent back to the main control processor. This feedback loop is essential for several key functions:

- Fault Detection: The board can detect abnormal current levels, indicating a fault like a short circuit or an overload. This allows the system to trigger protective measures, such as tripping a breaker or shutting down the equipment, to prevent damage.

- Closed-Loop Control: By providing real-time current data, the board enables the control system to make continuous adjustments to maintain the desired output, such as regulating the torque of a motor or the excitation of a generator.

- Power Management: It helps the system operate within safe limits and optimize energy efficiency.

- System Context: The DS200FCSAG1A is typically installed in the Power Conversion Cabinet for static starters or within the main control cabinet for a turbine. It receives power from the system’s control power supply (CPS) and is an integral part of the overall control and protection architecture.

In essence, this board acts as the system’s “eyes” on the power circuit. It provides the crucial data needed to ensure the equipment operates safely, reliably, and efficiently by monitoring the flow of electrical power.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922