الوصف

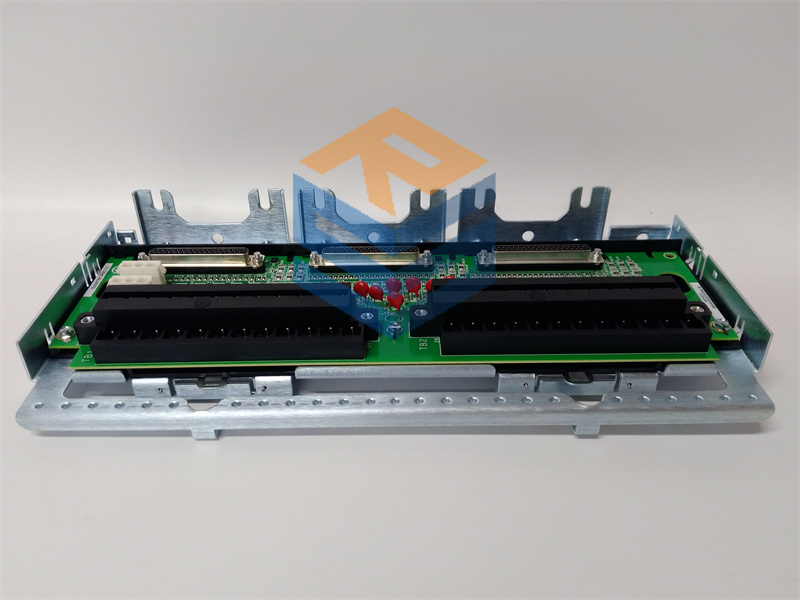

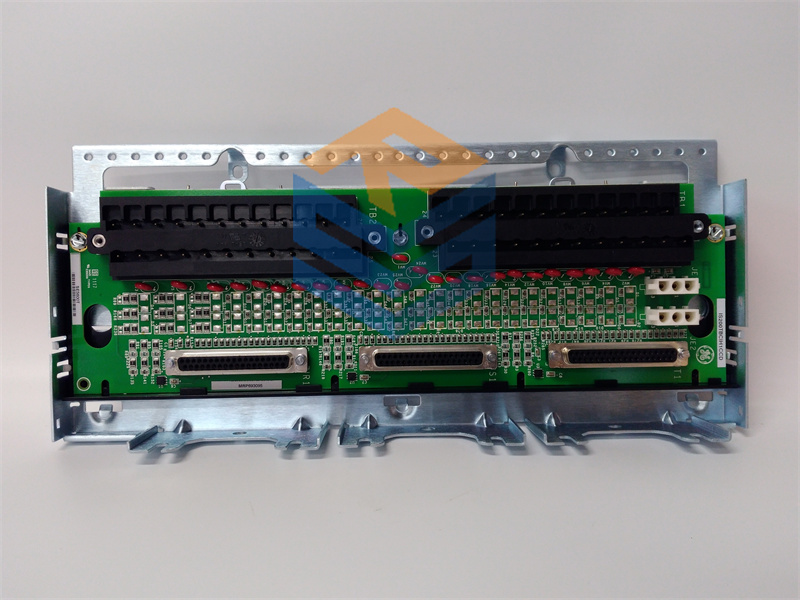

The GE DS200IMCPG1C is a Power Supply Interface PCB (Printed Circuit Board) used in GE’s industrial control systems, specifically within the Mark V series. This PCB plays a crucial role in managing electrical power supplied to various components in systems like turbine control and motor drives.

Key Features:

- Power Management: The DS200IMCPG1C effectively manages the distribution and regulation of power to the connected system components, ensuring they operate within specified voltage and current levels.

- Signal Conditioning: It handles input and output signals, facilitating communication between the power supply and control systems.

- Robust Design: Built for reliability in harsh industrial environments, the board is designed to withstand vibrations, temperature variations, and other demanding conditions.

Applications:

- Widely utilized in GE’s turbine control systems and industrial automation solutions.

- Integrates with other control modules and power supply systems to enable efficient operation of complex machines.

Maintenance and Troubleshooting:

- Visual Inspection: Regular checks for signs of damage, wear, or overheating can help in early identification of potential issues.

- Diagnostic Tools: Utilize available diagnostic software or tools for the GE control systems to analyze the health of the PCB and identify faults.

- Documentation: Always refer to the technical manuals specific to the DS200IMCPG1C for guidelines on installation, configuration, and troubleshooting.

For specific configurations, repairs, or replacements, it’s recommended to consult GE technical support or work with professionals experienced with GE systems and components.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922