الوصف

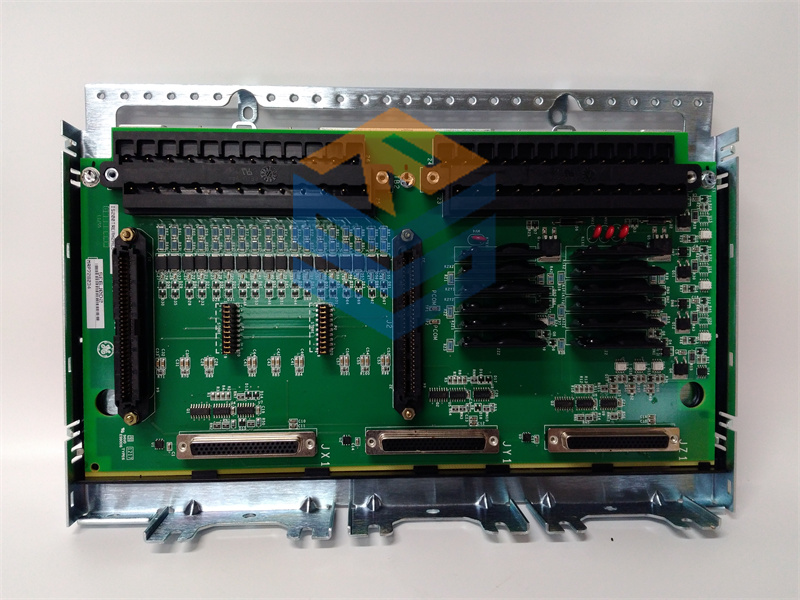

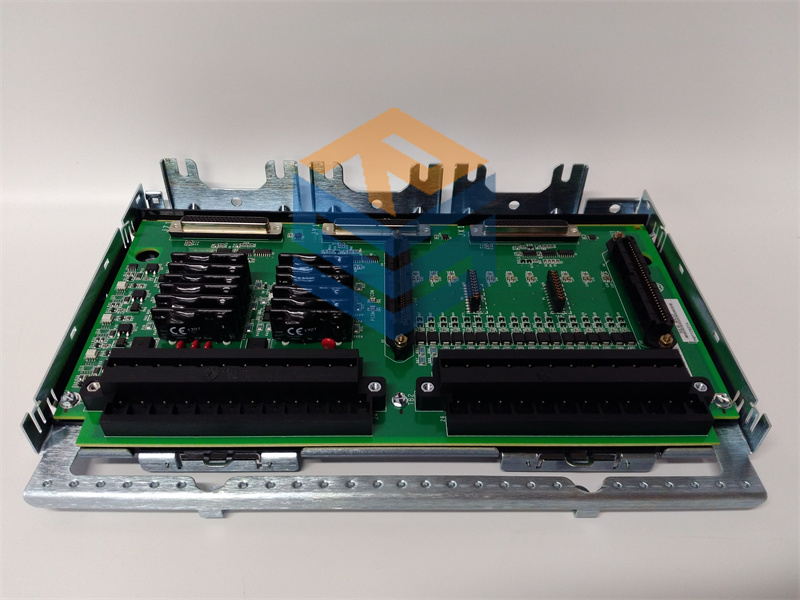

The GE DS200LDCCH1AHA is a specific model of the Drive Control/LAN Communications Board used in GE’s Mark VI control system. This board serves crucial functions in managing drive operations and facilitating communication within industrial environments, especially in power generation applications. Below, you’ll find an overview of its key features, functionalities, and related information.

Key Features:

- Dual Role:

- The DS200LDCCH1AHA board functions as both a drive control unit and a LAN communication interface, allowing for integrated control and real-time data exchange.

- Local Area Network (LAN) Communication:

- Provides robust LAN communication capabilities, enabling connectivity with other components of the GE Mark VI system. This connectivity is vital for coordinated control and monitoring.

- Drive Control Capabilities:

- Designed to manage electric drives effectively, regulating parameters such as speed, torque, and operational status to ensure optimum performance of motors and other drive systems.

- System Integration:

- The board is compatible with other modules within the Mark VI control system, facilitating seamless interaction and data exchange across the control network.

- Diagnostic Features:

- Equipped with diagnostic tools that help in monitoring system health, identifying faults, and aiding in troubleshooting processes. Indicators on the board can provide real-time feedback on its status.

Applications:

- Power Generation: Commonly employed in gas and steam turbine control systems where precision and reliability in drive operation are crucial for safety and efficiency.

- Industrial Automation: Utilized in various automated processes where coordinated control of multiple drives is necessary.

Maintenance and Troubleshooting:

- Regular Inspections:

- Schedule routine evaluations to check for physical damage, secure connections, and general wear on the board.

- Using Diagnostics:

- Take advantage of the onboard diagnostic capabilities to assess performance and quickly identify any issues that may arise, reducing potential downtime.

- Replacement Procedures:

- Should the board need to be replaced due to failure, follow the manufacturer’s guidelines for safe disassembly and replacement, ensuring that power is disconnected prior to any work.

Safety Considerations:

- Follow all appropriate safety protocols when interacting with electronic components. Always ensure electrical power is disconnected before performing maintenance and implement lockout/tagout procedures to prevent accidental energization.

Summary:

The GE DS200LDCCH1AHA Drive Control/LAN Communications Board is an essential component of the GE Mark VI control system, specifically designed for efficient drive management and communication in industrial settings, such as power generation. Regular maintenance, proper use of diagnostic features, and adherence to safety procedures are critical for maintaining the board’s performance and reliability.

If you need further details or assistance with the DS200LDCCH1AHA board, including operational insights or troubleshooting tips, please feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922