الوصف

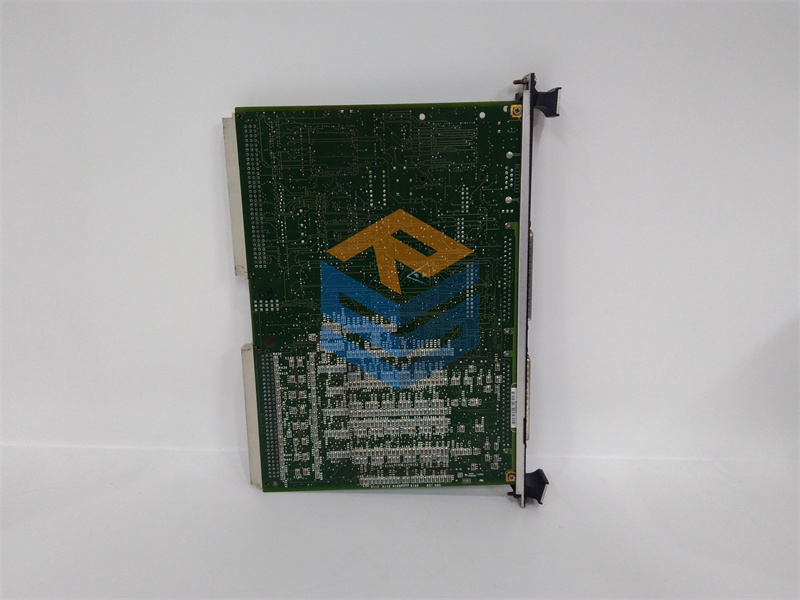

The GE DS200LDCCH1ALA is a model of the Drive Control/LAN Communications Board that is part of the GE Mark VI control system. This board is crucial in managing drive controls and facilitating communication in various industrial applications, particularly in power generation. Below is an overview of its features, functionalities, and applications.

Key Features:

- Dual Functionality:

- The DS200LDCCH1ALA board serves dual purposes: it manages drive control functions and enables LAN (Local Area Network) communications, facilitating seamless integration within the control system.

- LAN Communication:

- The board provides enhanced LAN communication capabilities, allowing for real-time data exchange between various components and modules of the GE Mark VI control architecture. This is essential for coordinated operations and monitoring.

- Drive Management:

- It is specifically designed to control electric drives, overseeing parameters such as speed, torque, and other operational metrics, ensuring optimal performance of motors and related equipment.

- Diagnostics and Monitoring:

- Integrated diagnostic features enable the board to continuously monitor its own performance along with the communication status, helping to identify any faults or issues quickly.

- System Integration:

- Fully compatible with other components of the GE Mark VI control system, the board works effectively with other modules for comprehensive system management.

Applications:

- Power Generation: Predominantly used in applications such as gas and steam turbines, where precise control of drives and effective communication are critical for performance and safety.

- Industrial Automation: Employed in various industrial processes that require coordinated control and monitoring of multiple drive systems.

Maintenance and Troubleshooting:

- Routine Inspections:

- Regularly check the board for any signs of physical damage, loose connections, and overall functionality to prevent operational issues.

- Diagnostic Tools:

- Utilize the onboard diagnostic features to monitor health and performance, enabling quick detection and resolution of any communication or control issues.

- Replacement Procedures:

- If a replacement is necessary, adhere to manufacturer guidelines for the safe removal and installation of the board. Always ensure that power is disconnected before servicing.

Safety Considerations:

- Follow all relevant safety protocols when maintaining or troubleshooting the board. Ensure that electrical power is turned off to avoid hazards and implement lockout/tagout procedures to ensure safety.

Summary:

The GE DS200LDCCH1ALA Drive Control/LAN Communications Board is a critical component in the GE Mark VI control system, designed to enhance drive management and communication efficiency in industrial environments, especially in power generation. Regular maintenance, proper utilization of diagnostic features, and adherence to safety measures are essential for sustaining the board’s reliability and performance.

If you need more specific information or have additional questions about the DS200LDCCH1ALA board, including troubleshooting tips or operational guidance, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922