الوصف

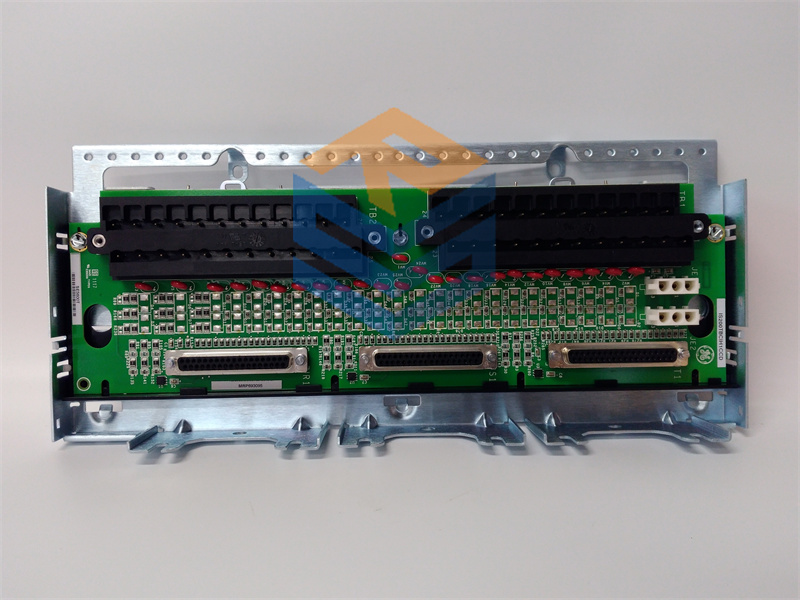

The GE DS200LRPBG1 Resolver Board is a component of the GE Mark VI control system, which is utilized in various industrial applications, particularly in power generation systems like gas and steam turbines. This board is primarily tasked with interfacing with resolvers, which are sensors used to determine the angular position or speed of rotating machinery.

Key Features:

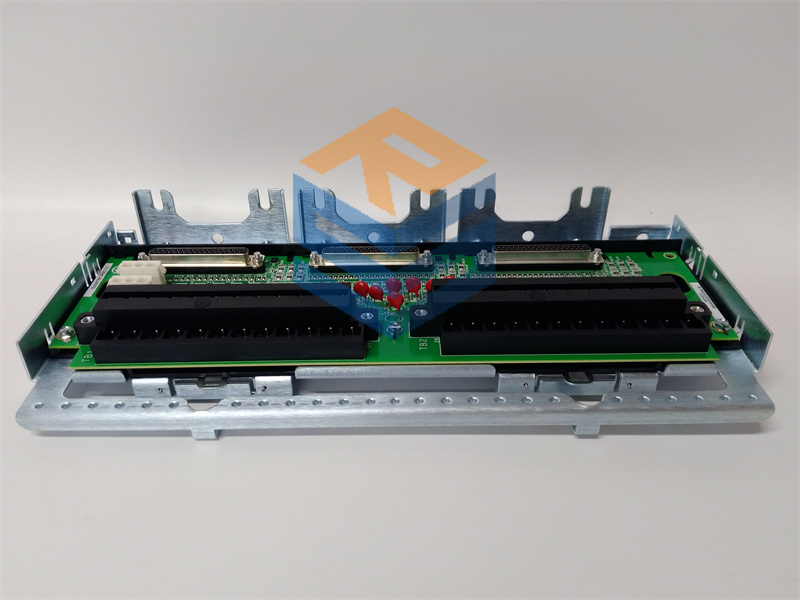

- Resolver Interface:

- The DS200LRPBG1 is designed to interface with resolver sensors to accurately measure position and speed. This is essential for applications that require precise motor control and feedback.

- Signal Processing:

- The board processes signals from resolvers and converts them into digital formats that can be used by the control system. This conversion allows the system to make informed decisions based on real-time data.

- High Precision:

- The resolver board provides high-resolution feedback, which is crucial for applications that demand precise control over rotation and movement, enhancing overall system performance.

- Integrated Diagnostics:

- It features diagnostic capabilities that monitor the health and performance of the resolver and the board itself. This aids in fault detection and helps ensure reliable operation.

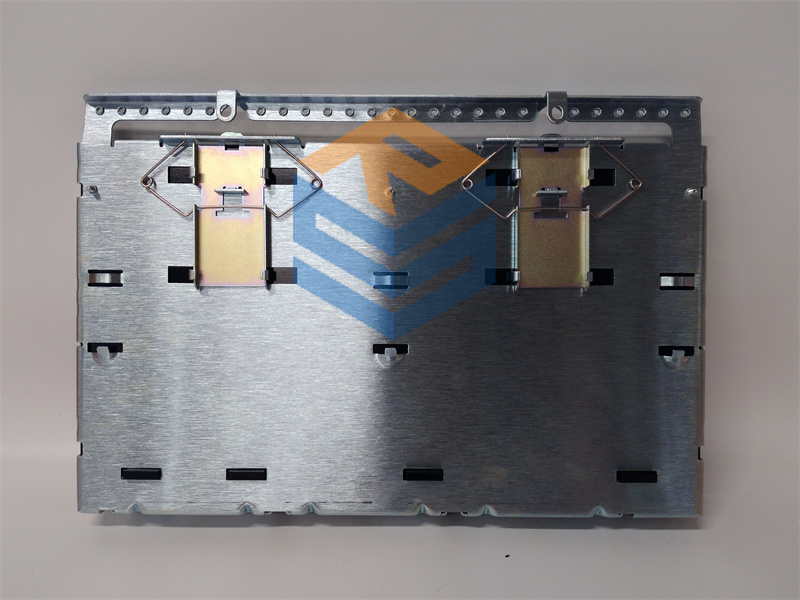

- Durable Construction:

- Built to withstand harsh industrial environments, the DS200LRPBG1 is designed for reliability and longevity, ensuring it can operate effectively in demanding conditions typical in power generation settings.

Applications:

- Power Generation: Primarily used in gas and steam turbine applications where precise feedback on rotor position and speed is essential for controlling system operations and ensuring safety.

- Industrial Automation: Useful in other industrial applications that require accurate rotational position and speed measurements.

Maintenance and Troubleshooting:

- Routine Assessments:

- Regularly inspect the resolver board for signs of wear, damage, or loose connections to maintain optimal operation.

- Diagnostic Monitoring:

- Utilize the board’s built-in diagnostics to monitor performance and detect potential issues early, allowing for timely maintenance and reducing downtime.

- Safe Replacement Procedures:

- If a replacement is necessary, ensure to follow safety protocols including disconnecting power and consulting the manufacturer’s guidelines for proper installation.

Safety Considerations:

- Always adhere to electrical safety standards and best practices when working with the DS200LRPBG1 Resolver Board. Implementing lockout/tagout (LOTO) procedures during maintenance activities is essential for safety.

Summary:

The GE DS200LRPBG1 Resolver Board is a critical component in the GE Mark VI control system, providing essential feedback for motor control through accurate position and speed measurements. Its robust design and diagnostic capabilities make it a valuable asset in power generation applications and other industrial settings.

If you need further details or have specific questions about the DS200LRPBG1 Resolver Board, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922