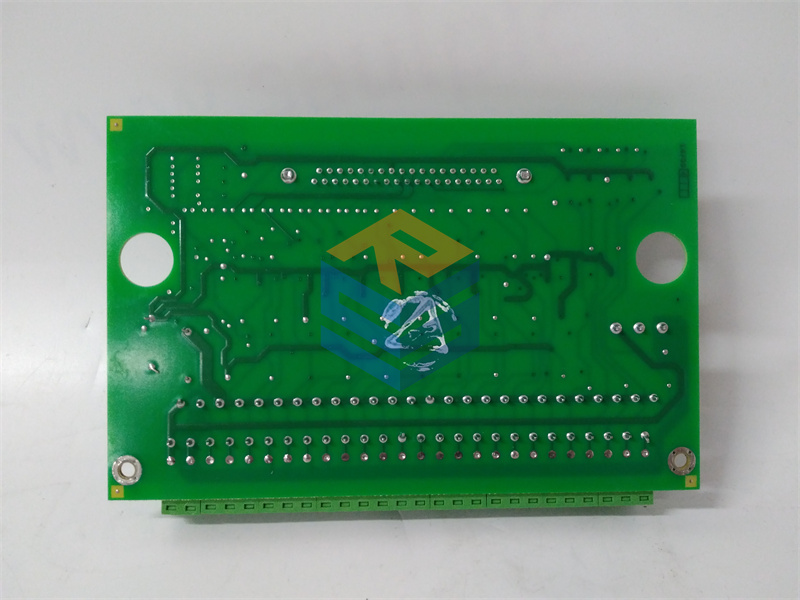

الوصف

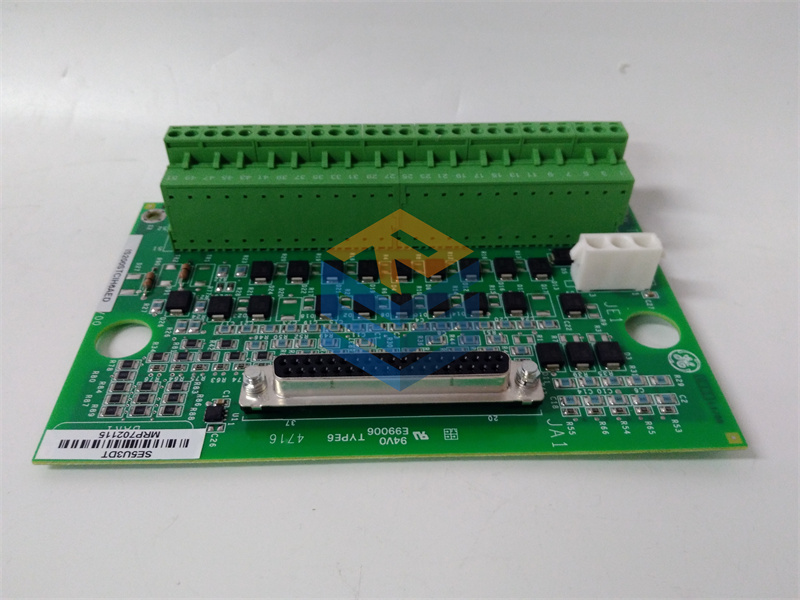

The GE DS200LRPBG1A resolver card is an important component within GE’s industrial control systems, specifically designed for applications in rotating machinery, such as turbines and motors. This card works with the resolver, a type of sensor that provides information about the position and speed of rotating elements.

Key Features:

- Resolver Signal Processing:

- The DS200LRPBG1A processes the electrical signals generated by resolvers. These signals are critical for determining the angular position and rotational speed of equipment, contributing to precise control and operation.

- Signal Conditioning:

- The card conditions the resolver signals to ensure accuracy and reliability before passing the data to the control system, reducing the impact of noise and interference.

- Real-Time Monitoring:

- It offers real-time monitoring capabilities, allowing for continuous assessment of the resolver’s performance and the operational state of the connected machinery.

- Integration with Control Systems:

- The resolver card integrates seamlessly with other components of GE’s control systems, enabling a coordinated and efficient management of rotating machinery.

- Diagnostic Functions:

- The DS200LRPBG1A includes diagnostic capabilities to help troubleshoot any issues that may arise with the resolver or the overall system, aiding maintenance and operational efficiency.

- Robust Design:

- Built for industrial applications, the card is designed to endure challenging environmental conditions, including temperature extremes, vibrations, and electrical noise.

- Alarm and Notification Features:

- Depending on the configuration, the resolver card may include alarm systems to notify operators of fault conditions or performance issues, thereby facilitating prompt actions to ensure operational safety.

Applications:

The DS200LRPBG1A resolver card is typically utilized in scenarios involving gas and steam turbines, electric motors, and other equipment where accurate feedback on position and speed is crucial for reliable operation.

Documentation and Support:

For detailed specifications, installation guidelines, operational instructions, and troubleshooting information for the GE DS200LRPBG1A resolver card, it is best to consult the official documentation provided by GE. Additionally, for technical support or service needs, reaching out to GE customer service or authorized support centers is recommended.

In summary, the GE DS200LRPBG1A resolver card is essential for accurate monitoring and control of rotating machinery, ensuring high performance and safety in various industrial applications through effective signal processing and integration with control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922