الوصف

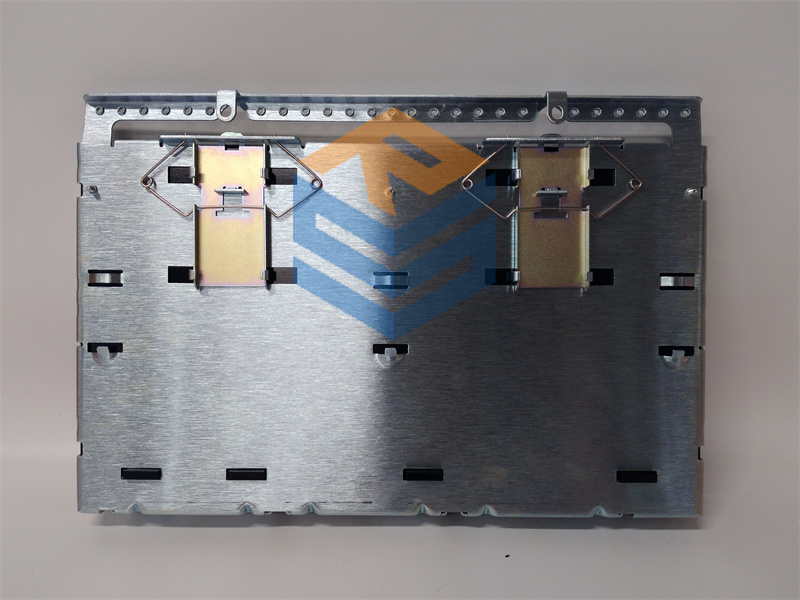

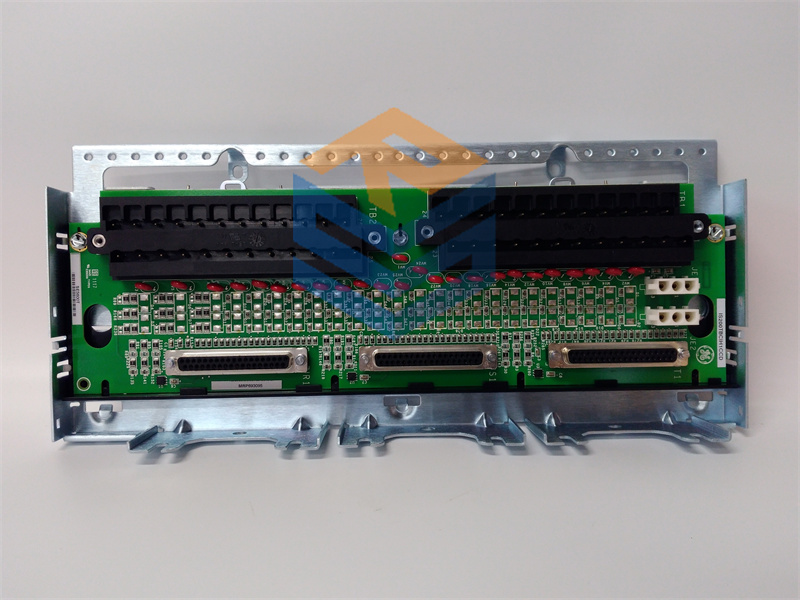

The GE DS200MBHAG1A is a Multi-Bridge Hub Communications Board used in the GE Mark VI control system. This board is essential for facilitating communication between various control modules and components in industrial environments, specifically in applications like power generation systems, including gas and steam turbines.

Key Features:

- Multi-Bridge Communication Capability:

- The DS200MBHAG1A supports multi-bridge communication, allowing multiple control and I/O modules to connect and communicate efficiently within the control system.

- High-Speed Data Transfer:

- This communications board enables high-speed data transfer across various modules, ensuring real-time data exchange that is critical for dynamic industrial processes.

- Diagnostic Capabilities:

- The board includes built-in diagnostic features that monitor system performance and communication links. These diagnostics help in early detection of issues, minimizing downtime and maintenance efforts.

- Reliable Construction:

- Designed to operate in demanding industrial environments, the DS200MBHAG1A is constructed for durability and reliability, ensuring it can withstand harsh conditions.

- Flexibility and Scalability:

- The module can be easily integrated into existing systems and reconfigured as needed, allowing users to tailor their control system according to specific application requirements.

- User-Friendly Interface:

- This board provides an intuitive interface for configuration and monitoring, making it easier for operators and maintenance personnel to work with and manage system communications.

Applications:

- Power Generation: The board is primarily utilized in gas and steam turbine control systems, helping to ensure effective communication and coordination among control elements to enhance operational efficiency.

- Industrial Automation: Beyond power generation, the DS200MBHAG1A can be employed in various industrial automation applications where reliable communication between different devices and systems is essential.

Maintenance and Troubleshooting:

- Routine Checks:

- Regular inspections should be conducted to ensure all connectors and terminals are in good condition and without corrosion.

- Diagnostic Monitoring:

- Utilize the onboard diagnostics features to continuously monitor system health, allowing for prompt identification and resolution of any communication issues.

- Safe Replacement Procedures:

- When servicing the board, adhere to safety standards, including disconnecting power before installation or replacement and following the manufacturer’s guidance.

Safety Considerations:

- Practicing electrical safety is crucial when working with the DS200MBHAG1A. Implementing lockout/tagout (LOTO) procedures during maintenance activities ensures a safe working environment for personnel.

Summary:

The GE DS200MBHAG1A Multi-Bridge Hub Communications Board is a critical component of the GE Mark VI control system, enabling vital communication and data transfer between various modules in power generation and industrial automation applications. Its reliability, diagnostic capabilities, and flexibility make it an essential element for maintaining efficient and effective operations.

If you have any specific questions or require further information about the DS200MBHAG1A Multi-Bridge Hub Communications Board, please feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922