الوصف

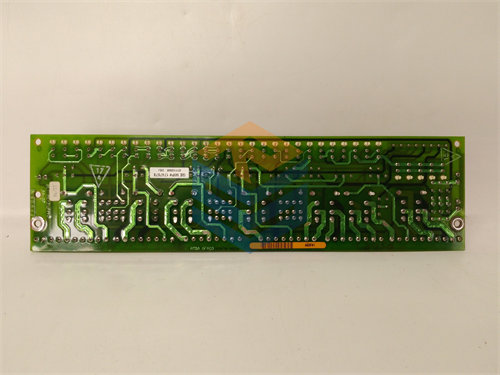

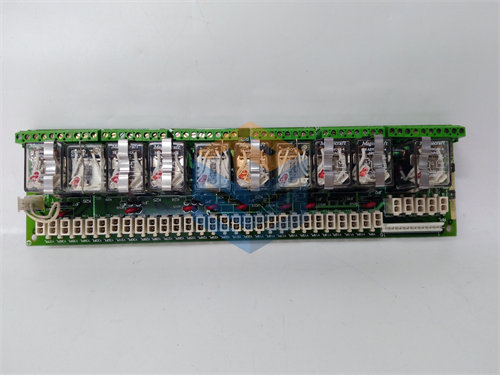

The GE DS200RTBAG3AHC is a Relay Terminal Board specifically designed and manufactured by General Electric (GE) for their Mark V Turbine Control System Series. This board is a crucial component within the control systems for gas, steam, and wind turbines.

Here’s a detailed breakdown of its features, function, and applications:

SEO-Optimized Top 10 Titles:

- GE DS200RTBAG3AHC: Relay Terminal Board for Mark V Turbine Control System.

- Essential for Turbine Control: GE DS200RTBAG3AHC Relay Board.

- DS200RTBAG3AHC: High-Density Relay Interface for GE Mark V Speedtronic.

- Optimizing Turbine Automation: GE DS200RTBAG3AHC Relay Terminal.

- Why Choose DS200RTBAG3AHC: 10 Relays, 52 Terminal Points, Robust Design.

- GE DS200RTBAG3AHC: Critical I/O for Gas & Steam Turbine Management.

- Legacy Control: The Role of DS200RTBAG3AHC in GE Mark V Systems.

- DS200RTBAG3AHC: Enhancing Signal Routing and Control Logic in Turbines.

- Reliable Relay Interface: GE DS200RTBAG3AHC for Drive Cabinets.

- DS200RTBAG3AHC: Powering Pilot Relays and Remote User Control.

Brief Product Description:

The GE DS200RTBAG3AHC is a Relay Terminal Board, identified by the “RTBA” functional acronym, designed for the GE Mark V Speedtronic Turbine Control System. It provides ten relays that can be driven directly by pilot relays or remotely by the user, serving as a versatile I/O hub. The board features 52 terminal points for various input/output connections, including Form C contacts for relays (Normally Open, Common, Normally Closed positions). It also includes stab connectors (CPH, CPN) for pluggable circuit control power. While part of a legacy series, the DS200RTBAG3AHC is vital for routing signals, controlling solenoids, and interfacing with critical turbine components, contributing to the overall automation, protection, and sequencing of turbine operations.

- Product Type: Relay Terminal Board

- Manufacturer: General Electric (GE)

- Series: Mark V Turbine Control System (Speedtronic)

- Function: Provides relay connections and signal routing for I/O purposes.

- Key Features: 10 relays, 52 terminal points, control power connectors.

- Application: Gas, Steam, and Wind Turbine automated drive assemblies.

Detailed Product Description:

As an expert in turbine control systems, I know that reliable relay interfaces are absolutely paramount. Turbines are complex machines with numerous actuators, solenoids, and protective devices that require discrete (on/off) control signals. The GE DS200RTBAG3AHC Relay Terminal Board is precisely engineered to manage these critical interactions within the robust and highly-regarded GE Mark V Speedtronic Turbine Control System. It acts as a bridge, taking signals from the main control processors and translating them into physical actions via its onboard relays, and vice-versa for status feedback.

Core Features and Functionality: Bridging Control and Action

The DS200RTBAG3AHC is more than just a simple terminal block; it’s an intelligent interface with several key features:

-

High-Density Relay Configuration: The board is equipped with ten relays. These relays are crucial for interfacing the low-voltage control signals from the Mark V processors with higher-power field devices like solenoids, motor starters, or protective trip circuits. The relays can be driven either directly from “pilot relays” (which might be other internal control signals) or remotely by the user (via the turbine control system’s logic).

-

Extensive Terminal Points (52): The presence of 52 terminal points makes this board a highly capable I/O hub. These terminals are used for a variety of purposes, including connecting to the Normally Open (NO), Common (COM), and Normally Closed (NC) contacts of the onboard relays (e.g., for K20 Form C contacts). This flexibility allows for diverse wiring configurations and integration into complex control schemes.

-

Relay Types and Protection: While specific relay types might vary slightly, information suggests it includes both DPDT (Double Pole, Double Throw) and 4PDT (Four Pole, Double Throw) relays, offering different contact configurations to suit various control requirements. Each relay is typically protected by a Metal Oxide Varistor (MOV), which provides surge suppression to protect the relay coil from voltage spikes. Individual diagnostic state lamps for each relay often indicate their energized state, aiding in troubleshooting.

-

Control Power Connectors (CPH/CPN): The board features two stab connectors, CPH (positive) and CPN (negative), which provide pluggable circuit control power (e.g., for pluggable circuits like C1PL through C5PL and Y9PL through Y37PL). This ensures that the relays and other onboard components receive the necessary operating voltage.

-

Configurability with Jumpers: The DS200RTBAG3AHC often includes Berg-type jumper pins (identified as JPx). These jumpers allow technicians to manually configure various parameters of the board to meet specific application requirements. Correct jumper settings are critical for proper functionality.

-

Robust Design and Coating: As a component designed for industrial environments, the board features a normal PCB coating style, which offers protection from environmental factors like dust, moisture, and minor chemical exposure. This coating enhances the board’s durability and reliability. The board also incorporates voltage suppression and regulation strategies using components like capacitors, resistors, and diodes.

-

Legacy System Support: It’s important to note that the Mark V series is considered a legacy product series, as its manufacture has been discontinued. However, due to its robust design and critical role, these boards are still highly sought after for maintenance, repairs, and system extensions in existing turbine installations worldwide. The “AHC” in the part number indicates specific functional and artwork revisions that distinguish it from earlier versions (e.g., DS200RTBAG3A).

The board is typically installed within the drive cabinet of the turbine control system, physically connecting to other boards and system components.

Technical Specifications (General for DS200RTBAG3AHC, specific details can vary by revision):

Applications:

The GE DS200RTBAG3AHC is specifically applied within the control and management systems of GE Mark V Speedtronic turbines, which are widely used in:

- Power Generation Plants:

- Gas Turbines: Controlling fuel flow (liquid/gas), speed, load, temperature, inlet guide vanes, and water/steam injection for emissions control (e.g., Dry Low NOx systems).

- Steam Turbines: Managing steam flow, speed, and other parameters for efficient power generation.

- Combined-Cycle Power Plants: Where both gas and steam turbines work in tandem, the Mark V system (and boards like the DS200RTBAG3AHC) coordinate their operations.

- Industrial Applications: While primarily for power generation, Mark V systems also control other industrial drive assemblies such as:

- Compressors: In pipelines or chemical plants.

- Pumps: For various process fluid movements.

- Generators: Beyond utility-scale power, in industrial settings for backup power or specific process needs.

The relays on the DS200RTBAG3AHC facilitate critical functions like:

- Solenoid Control: Activating/deactivating fuel valves, purge valves, or other pneumatic/hydraulic actuators.

- Protection Trips: Interfacing with overspeed detection, flame detection, and other safety shutdown circuits to activate protective relays.

- Sequencing: Managing the automated startup, shutdown, and cooldown sequences of the turbine and its auxiliaries.

- Operator Interface (indirectly): While operator commands are entered via HMI, the DS200RTBAG3AHC implements the discrete outputs based on those commands.

Related Products and Systems:

The GE DS200RTBAG3AHC is an integral part of the larger GE Mark V Speedtronic system:

- GE Mark V Speedtronic Control System: The overarching control system for which this board is designed. The Mark V utilizes a triple-redundant 16-bit microprocessor architecture for high reliability.

- GE Mark V Processors (e.g., R, S, T Processors): The main control processors that generate the logic signals that ultimately drive the relays on the DS200RTBAG3AHC.

- Other DS200 Series Boards: The DS200RTBAG3AHC is one of many boards in the DS200 series (e.g., DS200QTBAG1ADC RST Termination Board, DS200LDCCH1AGA Drive Control Board, DS200UPSAG1A Power Supply Board). These boards collectively form the I/O and control infrastructure of the Mark V system.

- Turbine Actuators and Sensors: The DS200RTBAG3AHC directly interfaces with these field devices, receiving status signals and sending control commands.

- EX2000 Excitation Systems: Some sources mention the DS200RTBAG3AHC as part of EX2000 excitation systems, indicating its role in power excitation control for turbine generators.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922