الوصف

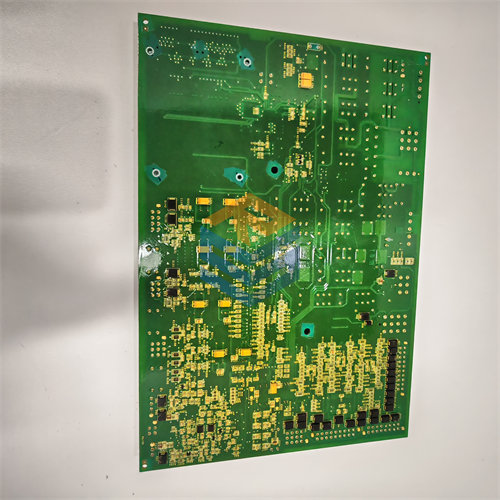

The GE DS200SDCCG4AHD Drive Control Board is an integral component of GE’s Mark V control system, primarily used in various industrial automation applications, especially in power generation settings such as gas and steam turbines. Below are the key features and details regarding this component:

Key Features:

- Drive Control: The DS200SDCCG4AHD manages the control of drive systems, regulating motor operations including speed, torque, and overall performance.

- Signal Management: It processes various input and output signals, communicating essential information between the control system and the connected drive, thereby facilitating real-time operation and control adjustments.

- Diagnostics Capabilities: This board typically includes built-in diagnostic features that enable the monitoring of performance metrics and help with troubleshooting by providing fault indications or operational alerts.

Applications:

- Power Generation: Commonly used in gas and steam turbine systems for effective control and management of turbine drives.

- Industrial Automation: Suitable for applications requiring precise control of motor functions and performance optimization in industrial settings.

Maintenance and Installation:

- Installation Precautions: Make sure to follow the specific GE guidelines for installation, including ensuring that the system is powered down before any maintenance or replacement work.

- Regular Diagnostics: Conduct routine maintenance checks using the diagnostic functions of the board to monitor health and performance, helping to proactively address any potential issues before they lead to system failures.

- Consult Technical Documentation: Keep technical manuals accessible for guide references related to installation instructions, wiring configurations, and troubleshooting guidelines tailored for the DS200SDCCG4AHD.

Additional Information:

- Replacement Considerations: Should the board require replacement, ensure that the exact model is sourced to maintain compatibility within the existing system. Engaging with qualified technicians for installation is advisable to ensure correct integration.

- Environmental Considerations: Ensure the operating environment adheres to the specified conditions to prevent any operational disruptions due to factors such as temperature extremes or dust ingress.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922