الوصف

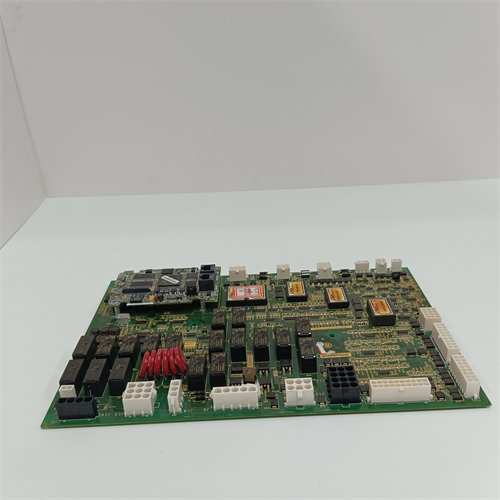

The GE DS200SDCIG1AGB Power Supply/Instrumentation Card (SDCI) is a crucial interface board designed for the GE Mark V Speedtronic Turbine Control System and DC2000 drives.1 It performs the dual function of generating stable, regulated logic power for the control circuits while simultaneously providing comprehensive instrumentation for monitoring critical AC line and DC motor signals.2

GE DS200SDCIG1AGB: Core Functionality and Specifications

The DS200SDCIG1AGB is a highly revised member of the SDCI board family.3 It provides essential power supplies to the system’s control logic and processes analog and digital signals from the drive components, ensuring accurate feedback for closed-loop control. The ‘G1’ designation indicates it is typically configured for systems utilizing an internal field exciter supply for Non-Reversing (NRX) control applications, often limited to 4$\le 10 \text{ A}$ field current.5

| Specification | Detail |

| Manufacturer | General Electric (GE) |

| Series Compatibility | Mark V Speedtronic, DC2000 Drives |

| Functional Acronym | SDCI (DC Power Supply and Instrumentation) |

| Key Output Power | Regulated $+5 \text{ VDC}, \pm 15 \text{ VDC}, \pm 24 \text{ VDC}, 115 \text{ VAC}$ |

| Instrumentation Role | Monitors Armature Current/Voltage, Field Current, AC Line Signals |

| Diagnostic Feature | LED indicators for onboard fuse status (e.g., FU1-FU5) |

DS200SDCIG1AGB: The Heart of Drive Control

The DS200SDCIG1AGB isn’t just a circuit board; it’s the tireless workhorse that ensures the integrity and stability of a high-performance drive system. Think of it as the Chief Power Regulator and Sensor Hub for a large DC motor.

Power Regulation: Clean and Consistent

Any seasoned controls engineer will tell you that the performance of digital control logic depends entirely on the cleanliness of the power supply. The GE DS200SDCIG1AGB takes the raw input power and meticulously transforms it into the various regulated DC and AC voltages needed by the other boards in the Mark V or DC2000 rack. The $+5 \text{ VDC}$ supply, which feeds the delicate microprocessors on the Drive Control Card (SDCC), must be impeccable—and this board delivers just that. Plus, the redundancy and protection built into the design, like the fuses (FU1-FU5), are non-negotiable for industrial reliability.6 Speaking of fuses, the illuminated LED indicators (like LT1, CR51, CR55) are a lifesaver; you don’t have to guess which fuse is blown—the light tells you instantly, drastically cutting down on frustrating troubleshooting time.7

Instrumentation: Real-Time Motor Health

What makes the SDCI unique is its secondary, yet equally vital, function: instrumentation. This board acts as a collector and conditioner for signals that tell the control system exactly what the motor and the AC line are doing.8 It monitors the armature current and voltage, the field current, the AC line currents, and even the voltage phase sequence.9 These measurements are crucial. They are converted into precise feedback signals that the main control card uses to execute speed and torque commands. Without the accurate, real-time data provided by the DS200SDCIG1AGB, the drive system would be essentially running blind. It’s the difference between a smooth, controlled startup on a large steel mill roller and a damaging overload trip.

Hardware Flexibility and Setup

The design incorporates several configurable hardware settings, which offers flexibility for plant personnel.10 For instance, the presence of Jumpers (JP1, JP2) and a Switch (SW1) allows technicians to customize certain operational parameters, such as the MD (Motor Direction) output control source or the AC contactor drop-out time.11 While these are typically factory-set, the ability to tune the board slightly for specific application needs—especially during a retrofit or modification—is a huge asset. It means one board can service a broader range of system configurations within the Mark V/DC2000 family, simplifying spare parts inventory.

Application Insight: The Mark V System

In a gas or steam turbine application using the Mark V Speedtronic system, the GE DS200SDCIG1AGB is fundamental. The turbine control processor needs constant, reliable power to execute its highly redundant and critical control algorithms. Moreover, the board often interfaces with the EX2000 Excitation Control Module, providing the field current and voltage feedback needed to regulate the generator’s output. The G1 version’s capability to handle internal low-level field supply streamlines this aspect of the control, making the overall system cabinet more compact and easier to manage.

Related Products and Alternatives

The industrial landscape is full of complementary and competing boards. For those working with the GE DS200SDCIG1AGB, here are a few other models and brands to consider:

- GE DS200SDCIG2AGB: This is the G2 version. The primary distinction is that G2 variants typically do not contain the internal field exciter circuitry (for $\le 10 \text{ A}$ field control) and are used when an external field exciter is required for higher current applications.

- GE DS200DCFBG1B: A related GE board (DCFB – DC Feedback Board), often found in similar drives, which shares the function of providing control-level power and motor signal feedback, though the specific circuitry and application context (like the EX2000 vs. DC2000) may differ.

- Bently Nevada 3500/15 Power Supply: Used in Bently Nevada’s condition monitoring rack, this unit serves the same purpose—providing regulated power to the critical monitoring modules—highlighting the universal need for dedicated, stable power in control and protection systems.

- Rockwell ControlLogix Power Supply (e.g., 1756-PA75): While a different architecture (PLC/DCS), the role is identical: taking source power and converting it into backplane power for I/O and processor modules. The GE board integrates instrumentation, whereas Rockwell uses separate I/O cards for that function.

- Honeywell PMDDC21 (DCS Power Module): Used in Honeywell’s TDC or Experion DCS systems, this is the dedicated power source for processor and I/O cards, providing high-availability power just as the SDCI does for the Mark V’s core electronics.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922