الوصف

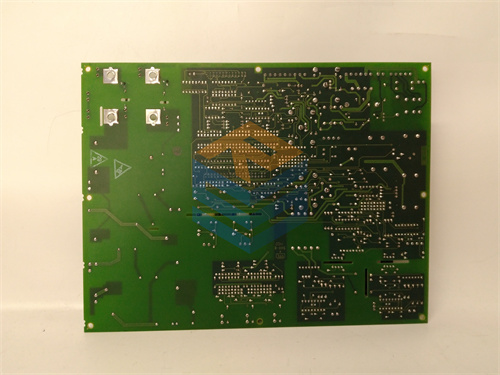

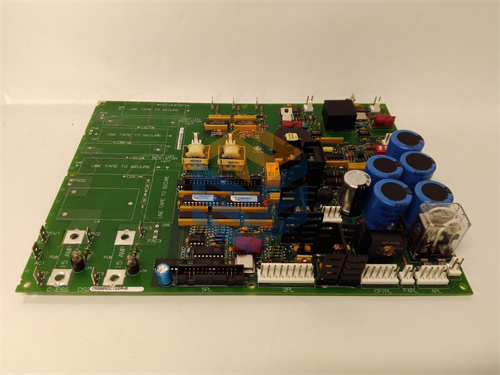

GE+DS200SDCIG2AEB DCS PLC Module

Product Name:

GE DS200SDCIG2AEB DCS PLC Module

Product Description:

The GE DS200SDCIG2AEB is a Distributed Control System (DCS) PLC module manufactured by General Electric (GE), designed to provide high-performance process control and automation in industrial applications. This module is part of the GE Mark VIe control system and is widely used in power generation, oil and gas, chemical processing, water treatment, and other mission-critical industries.

The DS200SDCIG2AEB module supports advanced signal processing, communication interfaces, and real-time control of various processes. It provides enhanced flexibility and scalability in system configurations, while also offering reliable performance for a wide range of applications. This module is engineered to integrate seamlessly with GE’s existing control systems, offering a redundant design that ensures system uptime in critical applications.

Product Parameters and Specifications:

General Information:

- Product Category: DCS PLC Module

- Model Number: DS200SDCIG2AEB

- Manufacturer: General Electric (GE)

- Control System: Part of the GE Mark VIe Distributed Control System.

- Primary Use: Process automation, real-time control, communication with field devices, and system monitoring in critical industrial sectors.

Key Features and Capabilities:

-

Signal Processing and I/O:

- Digital and Analog I/O: Supports both digital and analog input and output channels, allowing for the integration of various sensors, actuators, and control devices.

- High-Speed Signal Processing: Capable of processing complex signals with high speed and low latency, essential for real-time process control and feedback systems.

- Analog I/O Handling: Manages continuous signals like temperature, pressure, flow, and level, ensuring accurate process control.

-

Communication and Integration:

- Ethernet and Serial Communication: Supports Ethernet/IP, Modbus TCP, Modbus RTU, and GE’s proprietary communication protocols to communicate with other control systems and field devices.

- Real-Time Data Exchange: Enables high-speed data exchange across various control systems and equipment, ensuring that process data is transmitted with minimal delay.

- Remote Monitoring and Control: Facilitates remote diagnostics, monitoring, and troubleshooting, allowing operators to control and adjust settings from a centralized control room or via web-based interfaces.

-

Redundancy and Fault Tolerance:

- Redundant Controllers: Designed with redundant processing capabilities, ensuring that the system continues to operate in the event of a failure in one module or component.

- Failover Mechanisms: Incorporates failover mechanisms to maintain system reliability and ensure that no single point of failure will result in downtime.

-

System Configuration and Scalability:

- Flexible I/O Configuration: Can be configured to handle a wide range of I/O requirements depending on the application and process.

- Scalability: Easily integrates with larger systems, allowing users to scale up or modify the system as needed by adding more modules or adjusting system configuration.

- Hot-Swappable: Certain configurations allow for the hot-swapping of components without requiring a system shutdown, minimizing downtime during maintenance.

-

Environmental and Mechanical Specifications:

- Operating Temperature: Typically operates within a range of -40°C to 70°C, ensuring stable performance under extreme environmental conditions.

- Vibration Resistance: Built to withstand industrial-level vibrations, making it suitable for harsh factory and process environments.

- Electromagnetic Interference (EMI): Designed to meet strict EMI standards, ensuring the module operates reliably in environments with significant electrical noise or interference.

- Shock Resistance: The module can tolerate industrial shocks, ensuring stable operation in dynamic environments.

-

Safety and Compliance:

- Safety Standards: Compliant with international safety standards, including CE, UL, and RoHS.

- EMC Compliance: Designed to meet Electromagnetic Compatibility (EMC) standards to prevent electromagnetic interference from affecting nearby equipment.

- IS (Intrinsic Safety) Certification: May support intrinsic safety standards for hazardous areas, particularly in industries like oil and gas or chemical processing.

Electrical Specifications:

- Input Voltage: Designed to operate with 24 VDC or AC power input.

- Current Draw: Low energy consumption, optimized for continuous operation in industrial environments.

- Power Consumption: Approximately 12-20 Watts, depending on configuration and I/O usage.

Physical Specifications:

- Size: The DS200SDCIG2AEB module is typically rack-mounted or panel-mounted and fits standard control racks or enclosures.

- Dimensions: Approximately 7 inches x 12 inches x 3 inches (L x W x H), though exact dimensions may vary based on specific configuration.

- Weight: Typically weighs between 1.5 – 3 kg, depending on the exact configuration.

Applications:

-

Power Generation:

- Widely used in power plants, both fossil fuel and renewable, to control and monitor turbines, boilers, and generators, ensuring optimal energy production.

-

Oil & Gas:

- Ideal for use in refineries, oil rigs, and gas pipelines to monitor pumps, compressors, valves, and pressure systems for safe and efficient operations.

-

Chemical Processing:

- Deployed in chemical plants for controlling reactors, mixers, and filtration systems, managing parameters like temperature, pressure, and flow.

-

Water Treatment:

- Used in water treatment facilities for controlling pumps, filtration systems, and chemical dosing, ensuring consistent water quality and treatment.

-

Manufacturing and Automation:

- Applied in automated production lines, robotic systems, and material handling to improve efficiency and maintain process control.

Conclusion:

The GE DS200SDCIG2AEB DCS PLC Module is an advanced, high-performance module designed for industrial automation and real-time control of critical processes. With its reliable signal processing, flexible communication interfaces, redundancy features, and compliance with rigorous safety standards, this module is an excellent choice for industries such as power generation, oil & gas, chemical processing, and water treatment. The DS200SDCIG2AEB integrates seamlessly into GE Mark VIe systems, providing operators with a robust and scalable solution for managing complex control tasks in demanding environments.

CI522A 3BSE018283R1

CI534V02 3BSE010700R1

ABB CI541V1 3BSE014666R1

ICS TRIPLEX T8423

CI535V30 3BSE022162R1

ICS TRIPLEX T8431

SB510 3BSE000860R1

TC520 3BSE001449R1

ICS TRIPLEX T8402

RB520 3BSE003528R1

ABB RF533 3BSE014227R1

ABB PM511V16 3BSE011181R1

ABB SC510 3BSE003832R1

ICS TRIPLEX T8480

ABB SC520 3BSE003816R1

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922