الوصف

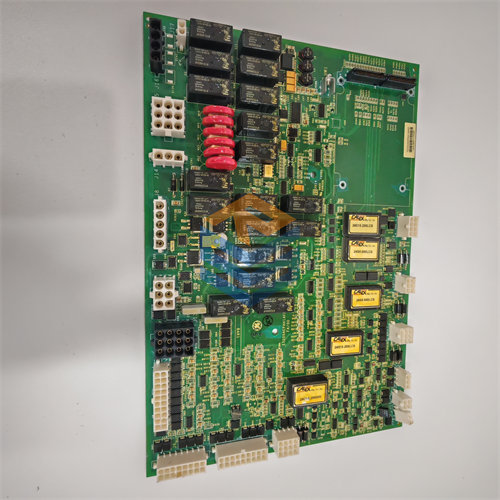

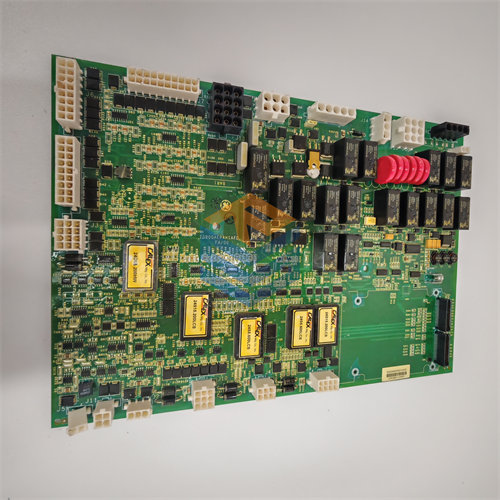

The GE DS200SHVIG1BDH is a highly specific revision of the SCR High Voltage Interface Board (SHVI) used in the GE Mark V Speedtronic Turbine Control System and the DC2000/EX2000 Drive Series.1

Its primary function is to serve as the isolated, signal-conditioning buffer that safely translates critical high-voltage and high-current feedback from the power section (the SCR bridge) into a reliable format for the drive’s low-voltage digital control system.

Core Functions of the DS200SHVIG1BDH

The SHVIG1BDH performs several crucial roles in the drive cabinet:

1. Isolation and Voltage Attenuation2

- Safety Barrier: It provides galvanic isolation to protect the sensitive control electronics and personnel from the hazardous high-voltage components of the Silicon Controlled Rectifier ($\text{SCR}$) power bridge.

- Metering: It attenuates (steps down) the high 3$\text{AC}$ line voltage and the 4$\text{DC}$ bridge voltage to a low, safe level suitable for the control system’s instrumentation circuits.5

2. Current Signal Conversion

This is vital for the drive’s closed-loop speed and torque control:

- Shunt Signal Input: It accepts the extremely sensitive, low-level 6$\text{mV}$ voltage signals (typically 7$\pm 500 \text{ mV}$) generated by the high-current shunts.8

- Frequency Conversion: It converts these 9$\text{mV}$ signals into a robust differential frequency output (ranging from 10$0 \text{ to } 500 \text{ kHz}$).11 Converting the signal to a frequency makes it highly resistant to the intense electrical noise in the drive cabinet, ensuring accurate transmission to the instrumentation board (SDCI or DCFB).

- Configurable Attenuation: The board typically includes up to 17 configurable jumpers that work with 12$10:1$ Current Transformers (13$\text{CTs}$).14 This feature provides user-selectable current attenuation to precisely match the board’s calibration to the specific current ratings of the installed power bridge.15

3. System Interfacing and Diagnostics

- Signal Routing: It acts as the bridge that connects the conditioned high-voltage/current feedback to the main control boards, including the Power Supply/Instrumentation Card (SDCI/DCFB) and the Power Connect Card (PCCA).16

- Diagnostics: The board is equipped with three onboard LED indicators that provide an immediate visual alert if a line filter fuse has blown.17

- Contactor Drivers: It often includes the necessary driver circuits for controlling both standard and fast contactors within the power system.18

Part Number Breakdown (DS200SHVIG1BDH)

The multiple trailing letters denote several functional and physical revisions over the life of the G1 SHVI product line:

| Segment | Code | Meaning |

| DS200 | DS200 | GE’s Mark V DS200 Series (Circuit board assembly) |

| SHVI | SHVI | SCR High Voltage Interface (Board) |

| G1 | G1 | Group 1: The primary functional grouping for this component type. |

| B | B | Functional Revision 1 |

| D | D | Functional Revision 2 (Indicates a specific functional or component update, backward compatible) |

| H | H | Artwork Revision (Indicates a specific version of the physical PCB layout) |

The DS200SHVIG1BDH is a highly evolved, reliability-focused component that is fundamental to the operational safety and performance of the GE drive system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922