الوصف

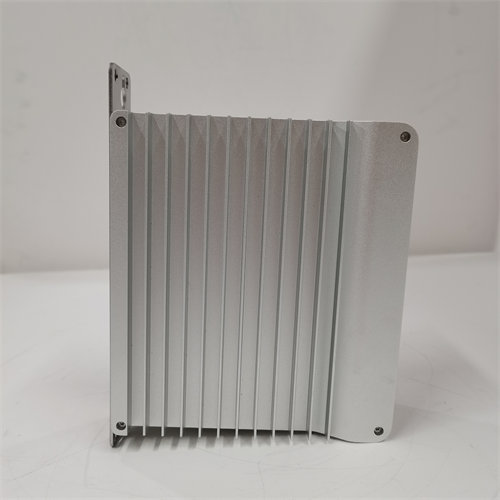

The GE DS200STCAG1A ARCNET LAN Driver Board, or STCA (Turbine Communication Board), is a critical component in the General Electric Mark V Speedtronic Turbine Control System. It doesn’t function as a simple terminal board but rather as a highly specialized Turbine Communication Processor that acts as the network master for the I/O cores.

In short, the STCA board is the data bridge and synchronizer for a Mark V core, responsible for processing incoming I/O signals, managing key control functions, and communicating across the internal network.

Key Functions and Role in the Mark V System

The DS200STCAG1A board is mounted within one of the redundant control cores (typically the R core) of the Mark V system and performs several vital, real-time control and communication tasks:

1. I/O Network Master (IONET)

The STCA is primarily the IONET Master for its I/O core. The IONET is an internal, high-speed network that allows the core processor to communicate with and control the other I/O and terminal boards within that specific core.

- Signal Processing: It receives signals (like pulse rate inputs, generator, and bus voltage inputs) from the various $\text{I/O}$ boards (e.g., TCQC, TCTG) and conditions, scales, and processes them before writing the data to the main $\text{I/O}$ Engine located on a daughterboard (like the UCPB).

- Data Distribution: It writes processed signals to the COREBUS connections on the terminal boards (e.g., QTBA or CTBA) to ensure the latest, conditioned data is available throughout the core.

2. ARCNET LAN Driver

The “ARCNET LAN Driver” designation refers to its role in managing communication across the system’s ARCNET local area network. This network enables data exchange between the main controller, the $\text{I/O}$ core, the protection module, and the operator control panel. This connectivity is essential for the system’s overall control and monitoring architecture.

3. Synch Check and Pulse Rate Processing

The board integrates specialized circuitry to handle critical turbine control functions:

- Synch Check Circuit: It performs the synchronization check by reading generator and bus voltage inputs. The result of this check is sent to other boards (like the TCTG) where it’s used to issue commands for the generator breaker synchronizing function. This is vital for safely connecting the generator to the electrical grid.

- Pulse Rate Input Circuit: It receives, scales, and conditions pulse rate inputs (which typically come from magnetic pickup devices monitoring shaft speed) to accurately track the high-pressure shaft speed, ensuring precise speed control and overspeed protection.

Hardware and Configuration

As a complex communication board, the DS200STCAG1A requires both hardware and software configuration:

- Hardware Jumpers: It is equipped with jumpers (like $\text{JP2}$ and $\text{JP4}$) used to enable test points for factory testing or select voltage for the flash EPROM device. These must be set correctly for proper operation.

- Software Configuration: Critical settings, such as pulse rate constants, synchronization settings, and compressor stall parameters, are entered and configured via the I/O Configuration Editor on the operator interface.

In summary, the DS200STCAG1A is much more than a simple terminal or driver; it is an intelligent communication hub and signal processor that allows the high-speed, triple-redundant control logic of the Mark V system to effectively monitor and command the physical turbine.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922