الوصف

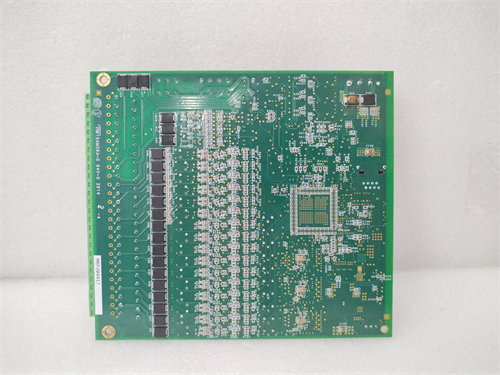

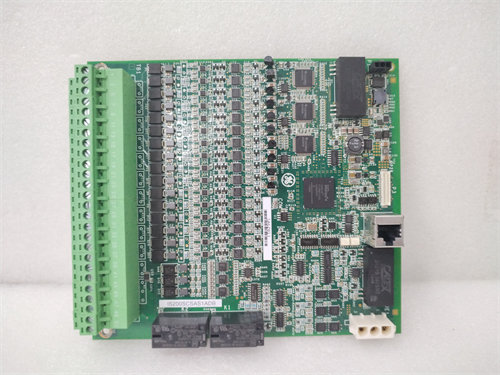

The GE DS200SVAAG1 Voltage Attenuator Board (often referred to by the acronym SVAA) is a printed circuit board designed for the General Electric Mark V Speedtronic Turbine Control System.1

Its primary function is to attenuate (reduce) high-level input voltages from field devices, such as various sensors, to a lower, safe, and measurable voltage range before the signals are sent to the system’s analog-to-digital converters and main control processors.2 This ensures that the sensitive electronic components of the control system are protected and that the signal processing is accurate.

Key Characteristics and Function

Voltage Attenuation

The core function of the DS200SVAAG1 is to reliably scale down analog voltage signals.3

- Signal Protection: Turbine control systems receive inputs from various sensors (like temperature, pressure, speed, and potentially generator signals) that can have a wide voltage range or high amplitude.4 The attenuator board, typically employing a resistive voltage divider circuit, reduces these high voltages to a standard, low-voltage range (e.g., $0-10\text{V}$ or $0-20\text{V}$) that the other $\text{I/O}$ boards can safely handle and convert.

- Precision and Accuracy: By converting the signal into a manageable range with a precise attenuation ratio (e.g., $10:1$ or $20:1$), it maintains the integrity of the measurement, which is crucial for the precise control and protection functions of the turbine.

Hardware Features

The board is a simple, non-processor-based circuit card with connections and diagnostic points.5

- Installation: It is designed to be easily installed and compatible with the modular architecture of the DS200 series boards within the Mark V cabinet.6

- Connectors: It features multiple terminals for attaching cables, which are often prefixed with an 7$\text{SC}$ designation (e.g., 8$\text{SC1, SC2}$), serving as the interface between the high-voltage field wiring and the internal control logic.9

- Diagnostics: Like many boards in the Mark V series, it includes test points that allow a qualified technician to measure the input and attenuated output voltages using test equipment to diagnose potential signal problems or board failure.10

In summary, the DS200SVAAG1 is an essential, passive interface board that acts as a protective and scaling bridge, making high-amplitude analog sensor data compatible with the digital processing environment of the GE Mark V turbine control system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922