الوصف

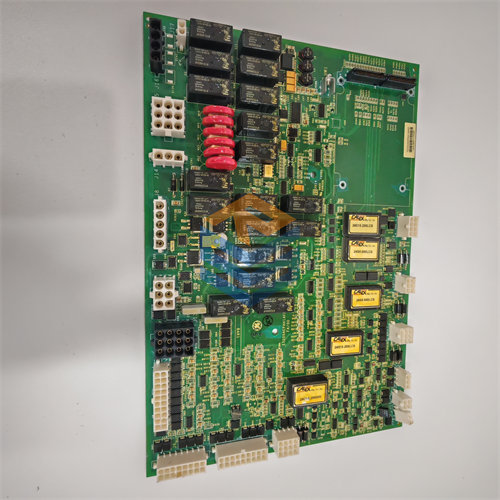

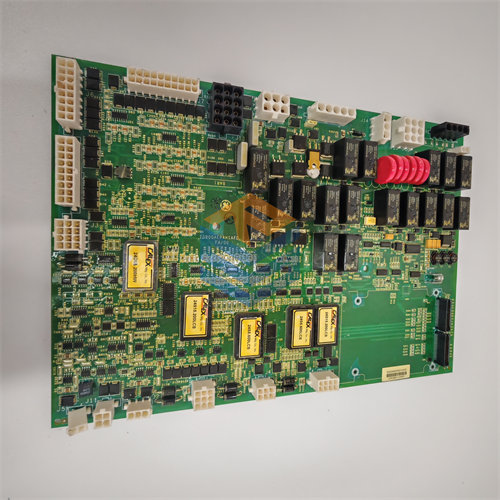

The GE DS200SVAAG1ACC Voltage Attenuator Board is a specific variant of the Voltage Attenuator Card ($\text{SVAA}$) for the General Electric Mark V Speedtronic Turbine Control System.

Its primary role is to reduce (attenuate) high-voltage signals from turbine field sensors to a lower, standardized voltage level that can be safely and accurately processed by the analog-to-digital converters within the Mark V control system.

Part Number Breakdown and Function

The part number $\text{DS200SVAAG1ACC}$ provides specific details about the board:

| Segment | Meaning | Detail |

| DS200 | System Series | Indicates the board belongs to the $\text{DS200}$ series of I/O cards, typically housed within the Mark V cabinet. |

| SVAA | Functional Acronym | Stands for Voltage Attenuator (or Card). This defines the board’s main function. |

| G1 | Product Grouping | Identifies the hardware group or form factor within the $\text{DS200}$ series. |

| A | Functional Revision | The first $\text{‘A’}$ indicates the first functional revision of the $\text{SVAA}$ design. |

| CC | Assembly/Coating Code | The two trailing letters, ‘CC’, indicate the specific coating and assembly style of the board. This often signifies a conformal coating for enhanced protection against moisture, dust, and contaminants in harsh industrial environments. |

Core Function

The board’s operation is based on resistive voltage divider circuits.1

- Signal Conditioning: It takes high-amplitude voltage signals from sensors (e.g., speed, pressure, temperature) and scales them down with a precise ratio (e.g., 2$10:1$ or 3$20:1$).4

- Protection: By reducing the high input voltage, it prevents damage to the sensitive electronic components in the downstream $\text{I/O}$ and processor circuits.

- Interface: It includes screw terminals (often labeled SC1, SC2, etc.) for connecting the field wiring and features test points for diagnostic measurements.5

In short, the $\text{DS200SVAAG1ACC}$ is a physically protected version of the standard Voltage Attenuator Card, ensuring signal safety and integrity within the turbine control system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922