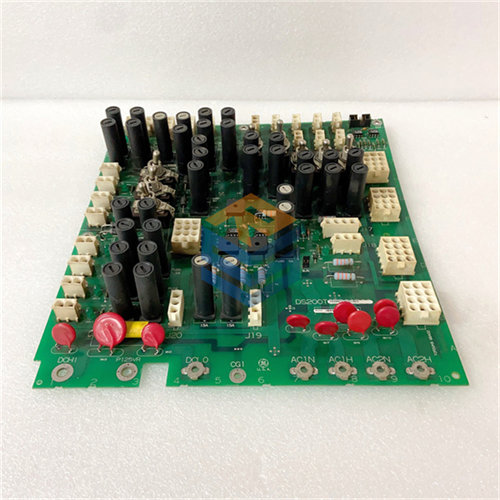

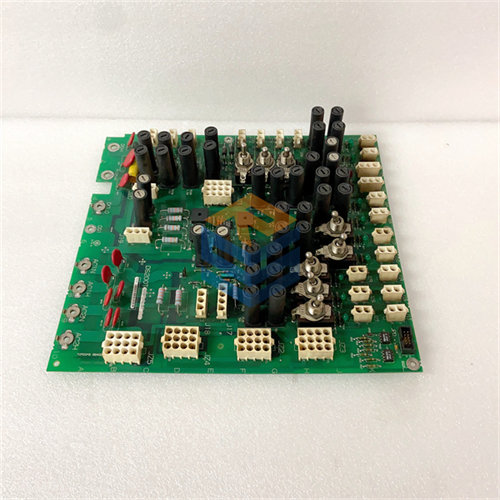

الوصف

The GE DS200TCCAG1A is a Common Analog Card for the Mark V Speedtronic turbine control system. It’s a general-purpose I/O board that provides the physical connections and signal conditioning for a wide variety of analog signals.

Technical Breakdown 🧠

This card’s function is to serve as a versatile interface, bridging the gap between the analog signals of field devices and the digital logic of the Mark V controller.

- Versatile I/O Interface: The “Common Analog” designation signifies the board’s ability to handle multiple types of standard analog signals, including 4-20 mA current loops and 0-10 VDC voltage signals. This flexibility makes it suitable for monitoring a broad range of parameters such as pressure, flow, vibration, and actuator position. It also provides analog outputs for controlling devices like proportional valves.

- Signal Conditioning: The card performs essential signal conditioning to ensure data integrity and accuracy. This includes filtering out electrical noise and interference, scaling the raw signal to a usable range, and providing a stable interface for sensitive field devices.

- System Integration: The DS200TCCAG1A is crucial for comprehensive system monitoring and control. It acts as the key interface for gathering all the necessary analog data from the turbine and its auxiliary systems, allowing the main control processor to make informed decisions for safe and efficient operation.

Applications 🏭

The DS200TCCAG1A is used in Mark V turbine control panels to:

- Monitor critical operational parameters like turbine speed, pressure, and temperature.

- Provide analog outputs to control hydraulic actuators, fuel valves, and other modulating devices.

- Integrate a wide variety of sensors from different manufacturers.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922