الوصف

The GE DS200TCCBG1ANE is a Common Extended Analog I/O Board that is a component of the GE Speedtronic Mark V Turbine Control System.

Its core function is to expand the system’s analog signal capacity by providing dedicated processing, scaling, and conditioning for a secondary group of analog inputs and outputs, particularly those related to temperature and current loops.

⚡ Function and Purpose

The DS200TCCBG1ANE board (functional acronym $\text{TCCB}$) serves as an I/O card within one of the Mark V’s control cores (R, S, or T). Its main roles include:

- Extended Analog I/O: It augments the primary analog I/O capabilities of the main control processor, allowing the system to interface with more field devices.

- $\text{RTD}$ Signal Conditioning: It contains the circuitry that supplies excitation to $\text{RTD}$ (Resistance Temperature Detector) sensors connected via the $\text{TBCB}$ (Terminal Board Common B) terminal board. It then processes and scales the $\text{RTD}$ input signals to provide accurate temperature readings to the main controller.

- Current Signal Processing: It provides the circuitry for handling common industrial signals like $\text{4-20 mA}$ and $\text{0-1 mA}$ analog current inputs.

- $\text{PT}$ and $\text{CT}$ Scaling: The board is also responsible for scaling and conditioning signals from $\text{PT}$ (Potential Transformer) and $\text{CT}$ (Current Transformer) inputs, which are crucial for monitoring electrical parameters on the turbine-generator.

🛠️ Hardware and Features

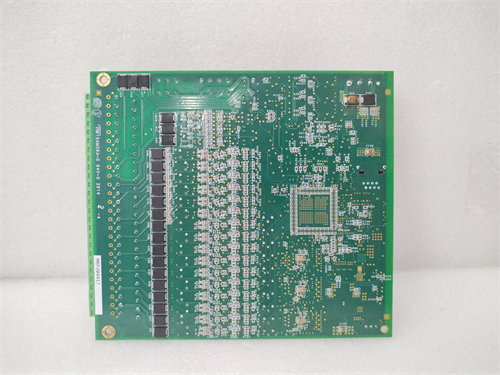

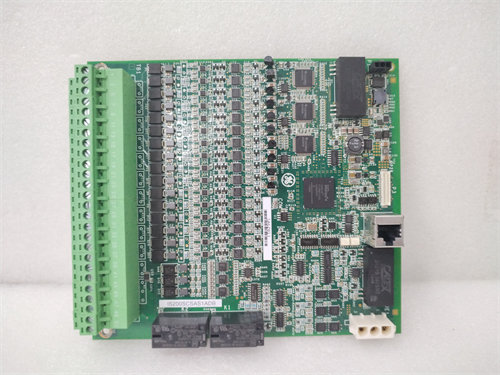

The $\text{DS200TCCBG1ANE}$ is a printed circuit board ($\text{PCB}$) with several key hardware components:

| Component | Detail |

| Processor | One 80196 microprocessor is utilized to execute the software for signal conditioning and processing. |

| Memory | Features multiple $\text{PROM}$ modules (Programmable Read-Only Memory) which contain the board’s operational firmware. During a replacement, these modules often need to be transferred to the new board. |

| Connectors | Includes two 50-pin connectors ($\text{JCC}$ and $\text{JDD}$) and one $\text{3PL}$ connector, which use ribbon cables to connect to the terminal boards and the I/O engine within the core. |

| Indicators | Contains one $\text{LED}$ (Light Emitting Diode), typically visible from the side, which provides a basic visual indication of the board’s status and health. |

| Jumpers | Features several manually-moveable hardware jumpers for customizing the board’s configuration based on the specific application requirements. |

The last part of the model number, “$\text{G1ANE}$,” signifies that this board belongs to the G1 hardware generation and has undergone multiple functional and artwork revisions (“$\text{ANE}$“) since the original $\text{G1}$ version.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922