الوصف

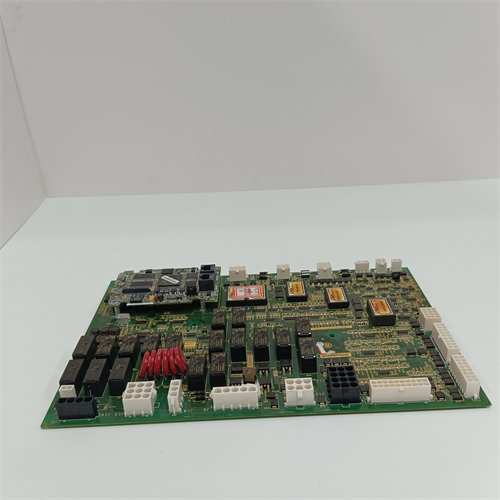

The GE $\text{DS200TCCBG2A}$ is an Extended Analog I/O Board designed for the General Electric Speedtronic $\text{Mark V}$ Gas and Steam Turbine Control System.

This board’s primary function is to process, scale, and condition additional analog input and output signals that are crucial for comprehensive turbine monitoring and control. The “$\text{B}$” in the product name ($\text{TCCB}$) signifies that it is the $\text{Extended}$ Analog I/O board, used to supplement the $\text{Mark V}$ system’s main Analog I/O capabilities.

🎯 Key Functions

The $\text{DS200TCCBG2A}$ board takes raw analog data from field devices and prepares it for use by the $\text{Mark V}$‘s central controllers ($\text{R}$, $\text{S}$, $\text{T}$).

- $\text{RTD}$ Input Processing: It acts as an $\text{RTD}$ (Resistance Temperature Detector) input control card, processing signals from $\text{RTD}$ sensors to accurately measure critical temperatures in the turbine, generator, and associated equipment.

- Current/Voltage Input Scaling: It conditions and scales common industrial process signals, such as 1$\text{4-20 mA}$ and 2$\text{0-1 mA}$ current loop inputs, which are used to monitor parameters like pressure, flow, and level.3

- Power System Monitoring: It handles voltage and current signals from $\text{PT}$ (Potential Transformer) and $\text{CT}$ (Current Transformer) inputs, which are necessary for calculating generator power, synchronization, and monitoring the electrical output.

🛠️ Technical Details

The board is an updated revision (denoted by the ‘$\text{G2}$‘ group number) of the original $\text{TCCB}$ design, ensuring full compatibility within the $\text{Mark V}$ architecture.

| Component | Function |

| Processor | One $\text{80196}$ Microprocessor ($\text{CPU}$) for local I/O processing and communication. |

| Memory | Multiple $\text{PROM}$ modules store the board’s operational firmware. These modules must typically be transferred to a replacement board to retain system-specific configuration and application software. |

| I/O Interface | Connects to its associated terminal board (like the $\text{TBCB}$ for $\text{RTD}$ and current inputs) via ribbon cables through connectors with IDs like $\text{JCC}$ and $\text{JDD}$. |

| Redundancy | Like many $\text{Mark V}$ boards, it supports the system’s $\text{Triple Modular Redundant (TMR)}$ design, often residing in the $\text{R}$, $\text{S}$, or $\text{T}$ cores to ensure fault tolerance. |

The final part of the designation, “$\text{G2A}$,” indicates the board’s group and revision level. The higher ‘$\text{G2}$‘ group usually represents a functional or component update compared to the $\text{G1}$ versions, but it remains electrically and functionally interchangeable for system upgrades.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922