الوصف

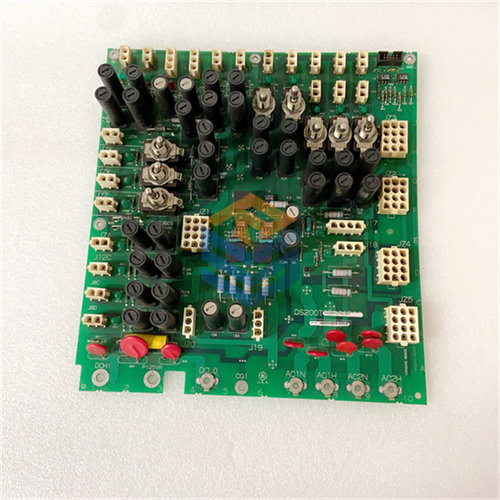

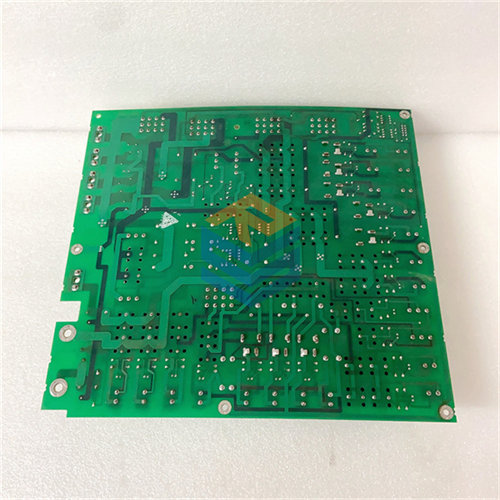

The GE DS200TCDAG2B is a Digital I/O Board for the Mark V Speedtronic turbine control system. It serves as the physical and logical interface between the turbine controller and discrete, on/off field devices. The “G2B” in the part number indicates a specific hardware revision.

Technical Breakdown 🧠

This board is a fundamental component for managing the on/off state of critical turbine equipment and monitoring alarm conditions.

- Digital I/O Processing: The DS200TCDAG2B is designed to manage both digital inputs and outputs. It receives contact inputs from devices like pressure switches and limit switches through specific connectors and transmits that information to the main processor. It also receives commands from the processor and sends contact output signals to energize or de-energize relays and solenoids.

- System Integration: This

TCDAboard is part of the Mark V’s digital I/O core, where it works in tandem with other boards. For instance, it takes contact inputs fromDTBAandDTBBterminal boards and sends contact outputs toTCRAboards. - Signal Conditioning & Diagnostics: The board includes circuitry for signal conditioning, such as noise filtering and electrical isolation, which is crucial for protecting the sensitive control electronics from the harsh industrial environment. It also features a block of 10 diagnostic LEDs that flash to indicate normal operation or an error code. An additional green LED on the side of the board provides a quick visual status check for operators.

- Hardware Revision (G2B): The

G2Bdesignation signifies a specific hardware version. This revision may include minor component updates or design improvements for enhanced reliability or manufacturability compared to earlier versions like theG1B. Functionally, it is an upgrade or direct replacement for the earlier version.

Applications 🏭

The DS200TCDAG2B is used in Mark V turbine control panels for:

- Monitoring the on/off status of critical turbine and auxiliary equipment.

- Controlling solenoids and relays for starting, stopping, and regulating turbine functions.

- Processing digital signals from emergency trip circuits and safety systems.

- Providing diagnostic feedback via on-board LEDs to help with troubleshooting and maintenance.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922