الوصف

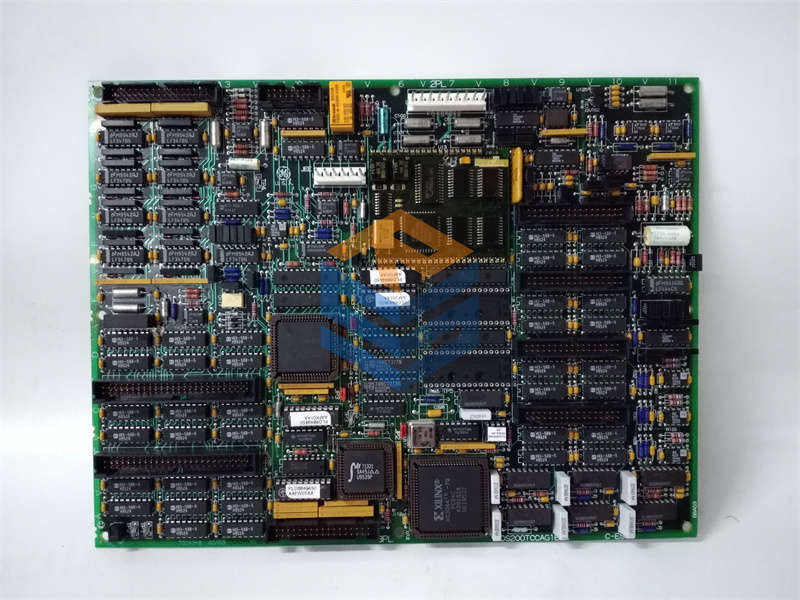

The GE DS200TCQEG2A is part of GE’s Mark V control system, specifically designed for the LM6000 gas turbine. This I/O Processor plays a vital role in managing input/output operations for the turbine control system, ensuring that signals are processed efficiently for operational safety and performance.

Key Features of the GE DS200TCQEG2A I/O Processor:

- Input/Output Management: The processor is responsible for handling various input and output signals from sensors, actuators, and other equipment involved in turbine operation.

- Data Processing: It processes real-time data to facilitate control actions and monitoring, contributing to efficient turbine management.

- Communication Interface: The I/O processor interfaces with other system components, facilitating necessary communication between the control system and field devices.

- Redundancy and Reliability: The design often includes features that support redundancy, enhancing the reliability of the turbine control system in critical applications.

Applications:

- Primarily used in the GE LM6000 gas turbine control systems, commonly found in power generation and industrial applications requiring high performance and reliability.

- Integrates within the Mark V control architecture, which provides comprehensive control capabilities for turbine operations.

Maintenance and Troubleshooting:

- Regular Diagnostics: Utilize built-in diagnostic tools to monitor the performance of the I/O processor and detect any potential issues.

- Connection Checks: Periodically inspect wiring and connections to ensure that inputs and outputs are functioning correctly and securely attached.

- Software Updates: Ensure that the firmware and associated software are updated regularly to maintain performance and add new functionalities.

- Technical Documentation: Refer to GE’s technical documentation for specific details on installation, configuration, and troubleshooting of the DS200TCQEG2A I/O Processor.

For in-depth technical support or specific queries regarding operation and configuration, consulting GE’s resources or a qualified service technician is recommended.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922