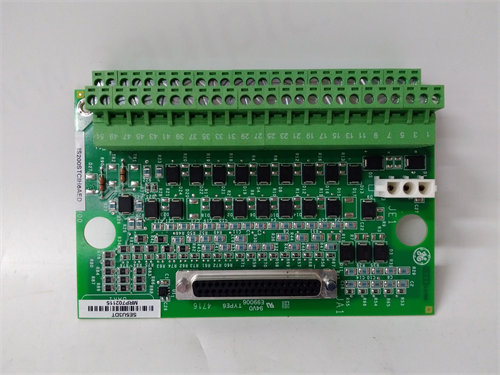

الوصف

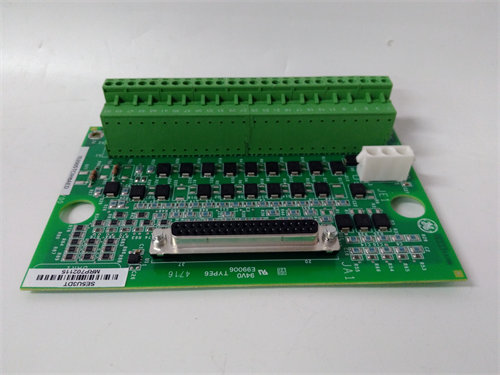

The GE DS200TCRAG1A is a Relay Output Board that is part of the GE Mark V control system. This board is crucial for controlling various field devices in industrial applications, particularly in gas and steam turbine control systems. Below are some key details and features about this board:

Key Features of the GE DS200TCRAG1A Relay Output Board:

- Relay Control: The board is equipped with relays that can be used to control external devices and systems, such as pumps, valves, and alarms. It provides the means to switch electrical loads on and off according to the control logic implemented in the system.

- Isolation: The relays offer electrical isolation between the control circuitry and the field devices, enhancing safety and reducing the risk of electrical interference.

- Multiple Channels: It typically supports multiple relay outputs, allowing for the control of several devices from a single board.

- Status Indication: The board may include indicators or LEDs to show the status of the relays, simplifying troubleshooting and operational monitoring.

- Compatibility: Specifically designed to integrate seamlessly within the Mark V control system, ensuring effective communication and coordination with other control modules and components.

Applications:

- Turbine Control Systems: Commonly used in gas and steam turbine applications to control various auxiliary devices based on signals received from the control system.

- Industrial Automation: Can be employed in various industrial automation processes where relay control is necessary for operational efficiency and safety.

Maintenance and Considerations:

- Regular Inspections: Ensure that the board is periodically checked for physical damage, loose connections, or signs of wear.

- Functionality Testing: Conduct regular tests to confirm that all relay outputs are functioning correctly and that any connected devices respond as expected.

- Firmware and Software Updates: Check if there are updates for the system software that may improve functionality or address known issues with the Relay Output Board.

- Consult Technical Documentation: Always refer to GE’s specific technical manuals for installation, configuration, and troubleshooting procedures related to the DS200TCRAG1A Relay Output Board.

- Seek Professional Support: If issues arise or further specialized assistance is needed, consult with GE’s technical support or a qualified technician with experience in the Mark V control systems.

For comprehensive specifications and detailed information, it’s recommended to review GE’s official documentation related to the DS200TCRAG1A Relay Output Board.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922