الوصف

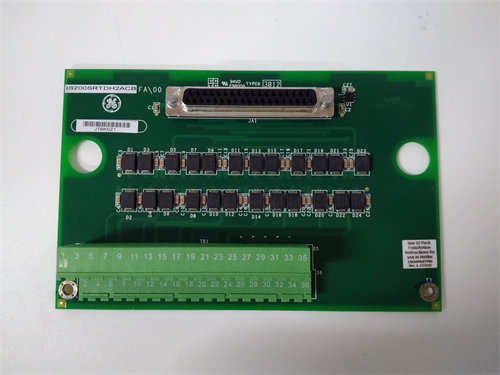

The GE DS200TCRAG2A is a Relay Output Board that is part of General Electric’s Mark V control system. This board plays a critical role in controlling external devices such as valves, motors, and alarms, particularly in turbine control applications.

Key Features of the GE DS200TCRAG2A Relay Output Board:

- Relay Outputs: The board is equipped with multiple relay outputs, allowing it to control various field devices based on signals received from the control system.

- Isolation and Protection: The design includes electrical isolation between the control logic and the relay outputs, which helps to protect sensitive components from electrical noise and potential surges.

- Status Indicators: The board typically includes status LEDs or indicators that provide visual feedback on the operational status of each relay, facilitating easier troubleshooting and monitoring.

- Durability: Built to withstand the rigors of industrial environments, the DS200TCRAG2A is designed for reliability and longevity.

- Integration: This board is compatible with the Mark V control system, enabling seamless integration with other components and modules within the control architecture.

Applications:

- Turbine Control Systems: The primary application of the DS200TCRAG2A Relay Output Board is in gas and steam turbine control systems, where it interfaces with various actuators and alarms to support operational control.

- Industrial Automation: This relay output board can also be utilized in broader industrial automation scenarios where process control is essential.

Maintenance and Considerations:

- Regular Inspections: Conduct routine checks to ensure that the board shows no signs of damage, corrosion, or loose connections.

- Performance Monitoring: Periodically test each relay output to confirm proper function and responsiveness, ensuring connected devices operate as intended.

- Documentation Reference: Consult the technical documentation provided by GE for specific installation, configuration, and troubleshooting guidelines related to the DS200TCRAG2A Relay Output Board.

- Firmware Updates: Keep an eye out for software or firmware updates that could enhance performance or address vulnerabilities.

- Professional Support: For specialized issues or when faced with troubleshooting challenges beyond routine checks, consider reaching out to GE technical support or a trained technician familiar with the Mark V system.

For precise specifications, installation instructions, and comprehensive operational information, it is recommended to refer to GE’s official documentation related to the DS200TCRAG2A Relay Output Board.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922