الوصف

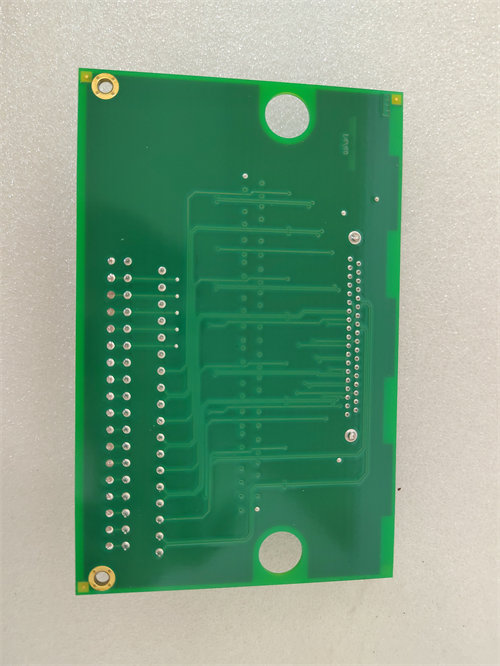

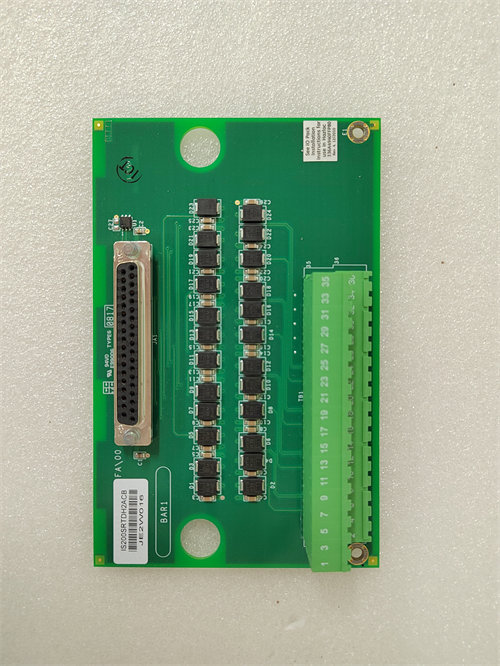

The GE DS200UCIAG1A is a vital component of the UC2000 series, specifically functioning as a mother board within the GE Mark V control system. This component is integral to the control and monitoring of industrial turbines, providing essential interfaces and processing capabilities.

Overview

- Application: The DS200UCIAG1A mother board is used in turbine control systems, particularly for steam and gas turbines. It is designed to handle multiple functions vital to system operation, including communication, processing, and connections to other modules.

Key Features

- Processor: The board typically houses a central processing unit (CPU) that executes control algorithms and processes data from various sensors and inputs.

- Input/Output Interfaces: This mother board provides numerous I/O interfaces that allow it to connect with various components, such as sensors, actuators, and other control modules, facilitating real-time data acquisition and control.

- Communication Protocols: The DS200UCIAG1A supports various communication protocols to ensure effective data exchange between the control system and peripheral devices, enhancing overall system performance and response times.

- Diagnostics and Monitoring: Integrated diagnostic features enable the monitoring of system health and performance, allowing operators to identify issues quickly and perform troubleshooting effectively.

- Robust Design: Built to operate in demanding industrial environments, the board is designed to withstand electrical noise, mechanical vibrations, and temperature fluctuations typical in turbine operations.

Installation and Maintenance

- Installation: Proper installation is crucial for the operational integrity of the board. Users should follow the installation guidelines provided in the manufacturer’s documentation to ensure compatibility and functionality.

- Regular Maintenance: Routine checks should be performed to ensure that the board and connected components are functioning correctly. Maintenance protocols may involve cleaning, checking connections, and updating firmware or software as needed.

Documentation and Support

For specific information regarding installation procedures, configurations, and operational guidelines for the DS200UCIAG1A mother board, it is essential to refer to the official GE documentation. Additionally, for technical support or troubleshooting assistance, contacting GE’s technical support will provide valuable resources and expert advice.

If you have any further questions or require additional information about the GE DS200UCIAG1A mother board, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922