الوصف

As an expert in industrial automation, I can provide a detailed and high-quality description of the GE DS200UCIAG2A board.

1. Enhanced SEO Titles

- GE DS200UCIAG2A: UC2000 Main Control Card for Mark V Turbine Systems.

- GE DS200UCIAG2A: The Central Processor Board for GE EX2000 & Mark V.

- Unit Controller DS200UCIAG2A: The Motherboard of the UC2000 System.

- GE Mark V DS200UCIAG2A: High-Performance Main Control Board.

- DS200UCIAG2A: The Brain of GE Turbine Excitation and Control Systems.

2. Brief Product Description

The GE DS200UCIAG2A is a specialized UC2000 Main Control Card, also known as the Unit Controller Motherboard, designed for use in the GE Speedtronic Mark V and EX2000 series control systems. This board is the central processing unit (CPU) for the UC2000 unit, serving as the main printed wiring board. It’s the “brain” of the control unit, providing the foundation for mounting other critical boards, such as the UCPB (CPU Daughter Board) and GENI (Genius I/O) boards. It is responsible for a wide range of functions, including executing complex control algorithms, managing I/O, and ensuring the seamless operation of the turbine’s excitation control system.

- Part Type: Main Control Card / Motherboard

- Primary Function: To serve as the central processor and a foundation for other boards within the UC2000 unit.

- Compatibility: GE Speedtronic Mark V and EX2000 series control systems.

- Application: Turbine control, excitation control, and other industrial automation tasks.

3. Detailed Product Description

In the complex world of power generation, the control system is the nerve center of the operation. The GE DS200UCIAG2A is not just a component; it is the central nervous system of the UC2000 unit within the larger GE Mark V or EX2000 control systems. From my experience, this board’s function is far more than just a passive motherboard. It is an active processor that manages the flow of data, controls system redundancy, and ensures that the turbine’s operations—from startup to shutdown—are executed with high speed and precision.

A Closer Look at the DS200UCIAG2A

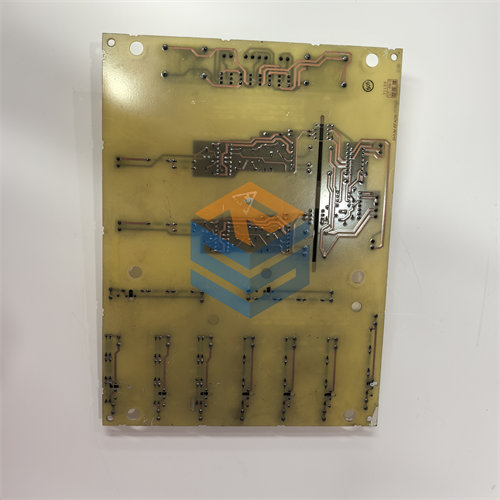

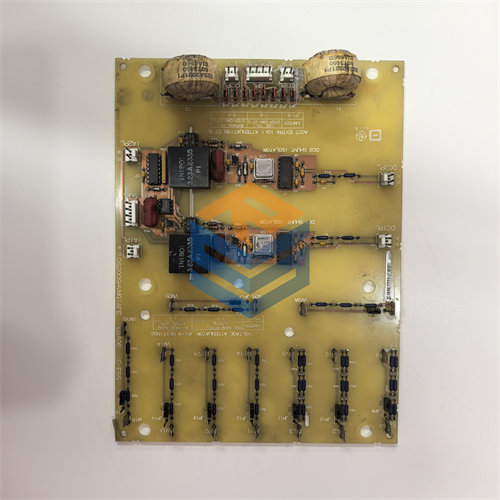

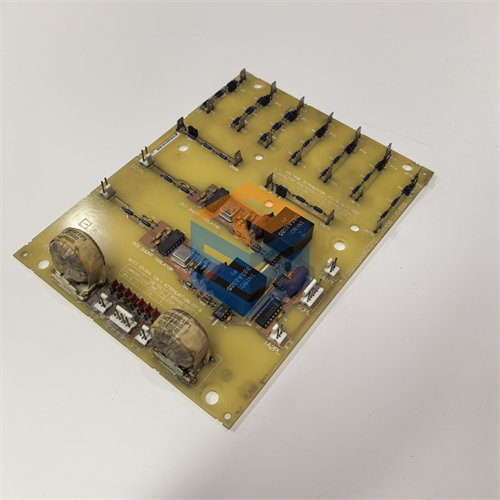

The DS200UCIAG2A is engineered as the core of the UC2000 unit. It is a large, feature-rich board that provides the physical and electrical framework for the unit’s computing power. It’s often located in the <R> core, or Control Engine core, of the system. The board contains a microprocessor (often an Intel 80196 processor) and multiple slots for mounting a variety of daughterboards, including:

- DS200UCPB (CPU Processor Board): This is the core CPU daughterboard that gives the UC2000 its primary processing power. The UCIA serves as the motherboard for this processor.

- PANA (ARCNET No-LAN Driver Board): This board handles communications over the ARCNET network.

- GENI (Genius I/O Boards): These boards provide the interface to the GE Genius bus, a popular network for connecting a wide range of I/O devices.

The UCIA’s primary role is to act as a data concentrator and processor. It takes data from various sources, including the XDSA (from the fuel skid), processes it with its onboard processor, and then passes the information on to the main CPU (on the UCPB board) to be used by the control sequence software. This pre-processing function allows the main CPU to focus on executing control logic, rather than on the raw data acquisition and conditioning.

Key Features and Benefits

- High-Speed Processing: The board and its daughterboards are equipped with powerful processors capable of handling complex algorithms and real-time control tasks efficiently. This is crucial for maintaining precise control over turbine operations.

- Foundation for System Expansion: As a motherboard, the DS200UCIAG2A provides the connectors and infrastructure for adding other boards, which allows the control system to be easily expanded to meet new I/O requirements without a full system replacement.

- Redundancy and Reliability: The UCIA is a part of the Mark V’s renowned TMR (Triple Modular Redundancy) architecture. In a redundant system, multiple UCIA boards work in parallel to ensure high reliability and system uptime.

- Onboard Diagnostics: The board features diagnostic LEDs and test points to simplify troubleshooting. These indicators can provide valuable information about the status of the board, power supply, and communication buses, helping technicians quickly identify and resolve issues.

- Robust Industrial Design: Built to the high standards of GE’s industrial equipment, the board’s robust design and protective coating help it operate reliably in harsh industrial environments with dust, temperature fluctuations, and electrical noise.

Technical Specifications

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922