الوصف

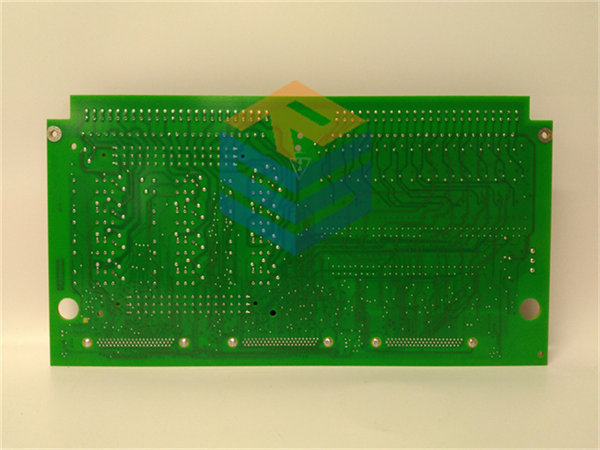

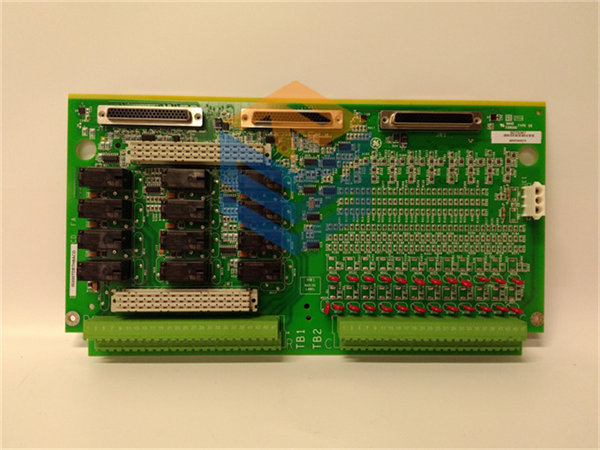

The GE DS2020BRCAG3 is a Dynamic Brake Control Assembly Module used in the General Electric Mark V Series of Turbine Control Systems and GE Drive Control Systems.

Its full functional name is often described as a 15 Amps Brake Control Assembly.

🛑 Core Function: Dynamic Braking Control

The primary function of the DS2020BRCAG3 is to manage the Dynamic Braking System for large motor-driven machinery, such as a turbine’s rotor or associated equipment in a power generation system. Dynamic braking is a method used to rapidly and efficiently stop or decelerate a rotating machine by converting its kinetic energy into thermal energy for dissipation.

The module performs several critical safety and control functions:

- Braking Activation & Release: It receives signals from the turbine’s main control unit (the control logic) to precisely activate and release the mechanical or electrical braking system for smooth and controlled deceleration.

- Deceleration Control: It ensures that the motor-driven equipment decelerates at a controlled rate, preventing abrupt stops that could cause mechanical stress or damage.

- Energy Dissipation: It controls the process of converting the motor’s kinetic energy into heat, which is then safely dissipated, typically through dynamic braking resistors.

- Overspeed Protection: The module is integrated with the turbine’s safety mechanisms and will automatically engage the brakes if the turbine’s speed exceeds predetermined safe limits, which is a critical safety feature.

- Current Regulation: It manages the current supplied to the brake actuator, handling up to 15 Amps of current, and includes protection features against overcurrent and thermal stress to ensure system reliability.

📝 Key Specifications

| Specification | Detail |

| Series | GE Mark V Speedtronic Turbine Control System (DS2020 Series) |

| Functional Acronym | BRCA |

| Product Type | 15 Amps Brake Control Assembly Module |

| Maximum Current | 15 Amps (Current Regulation) |

| Power Supply | Typically requires a $\text{28 V dc}$ power supply |

| Output Channels | Contains $\text{12}$ relay channels |

| Mounting | Designed for $\text{DIN-rail mounting}$ |

| Environment | Built to withstand industrial conditions (e.g., $5\%-\text{95\%}$ non-condensing humidity) |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922