الوصف

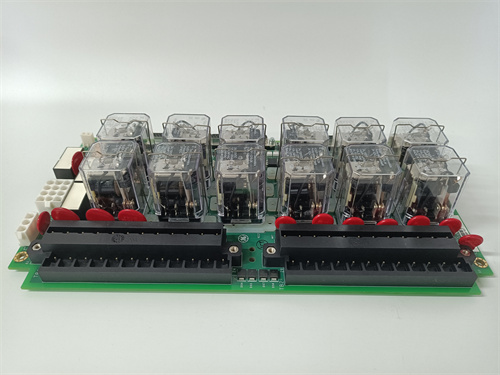

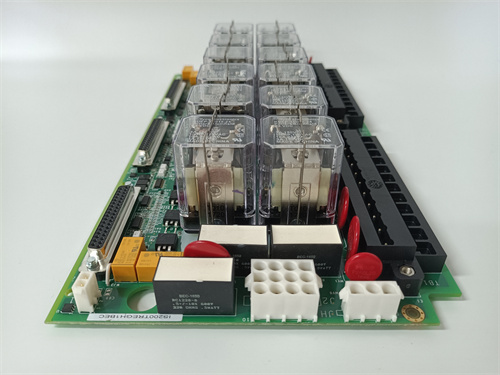

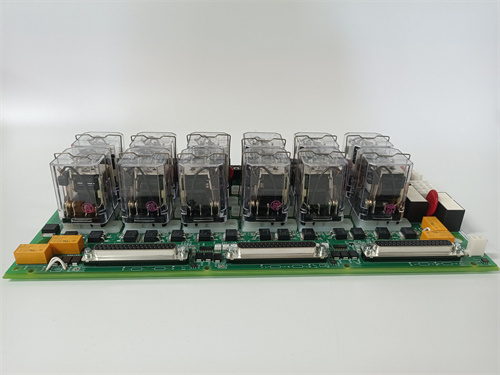

The GE DS2020BRCAG Brake Control Assembly is a crucial component for industrial drive and turbine control systems, specifically within the General Electric Mark V Series.

The primary function of this module is to provide precise control over the dynamic braking system to ensure the safe and efficient deceleration and stopping of motor-driven machinery, such as gas or steam turbines.

🛑 Key Functions and Features

The “BRCA” in the part number often stands for “Brake Control Assembly,” and it is designed to manage the process of rapidly and smoothly stopping a high-inertia system.

| Function | Description |

| Dynamic Braking Control | Manages the entire braking sequence, converting the motor’s kinetic energy into thermal energy that is safely dissipated, often through braking resistors (not included with the board itself). |

| Precise Deceleration | Utilizes advanced control logic to ensure the motor decelerates at a controlled rate, preventing mechanical shock and stress on the drive components. |

| Overspeed Protection | Integrates with the turbine’s safety mechanisms to automatically activate the brakes if the motor/turbine speed exceeds safe operating limits. |

| Current Regulation | Manages the current supplied to the brake actuator, such as solenoids (with some versions handling up to 15 Amps), ensuring stable performance and preventing electrical damage. |

| Integration | Designed to integrate seamlessly with the main control unit of the Mark V system, receiving signals to activate or release the brakes. |

⚙️ Technical Context

- Product Series: It belongs to the DS2020 family within the legacy GE Speedtronic Mark V Turbine Control System Series and is also used in GE Drive Control Systems.

- Module Type: It is typically a specialized circuit board or modular assembly (a PCB with attached hardware components) that is mounted within the drive cabinet.

- Operating Environment: Like other modules in the DS2020 series, it is built for demanding industrial environments, with robust features like resistance to vibrations and a wide operating humidity range (5-95% non-condensing).

Due to the critical safety function of this module, it is engineered for high reliability and often comes with features like thermal and electrical protection for enhanced system safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922