الوصف

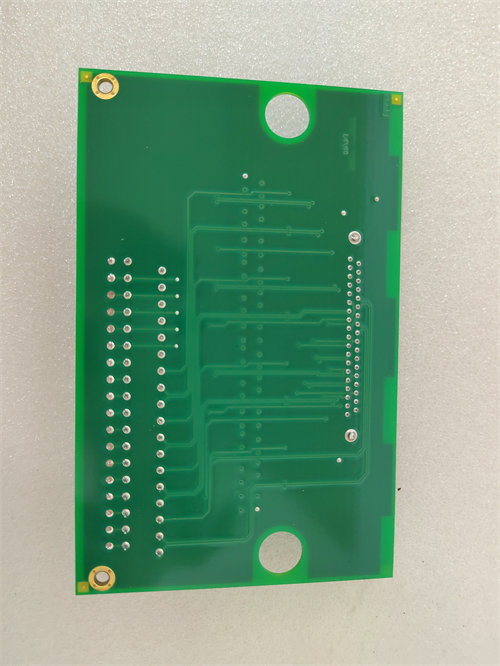

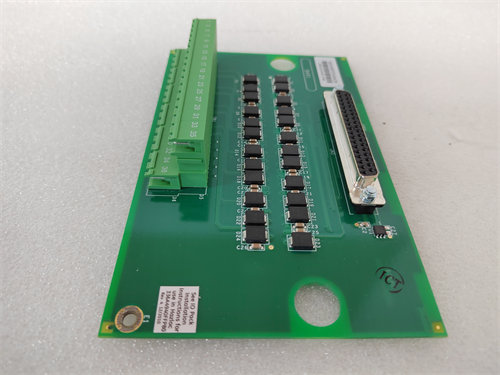

The GE DS215DMCAG1AZZ02A is a critical, highly-integrated printed circuit board assembly used in General Electric’s industrial control systems, most famously the Speedtronic Mark V Turbine Control System.

The designation “DOS Main Control Board” often refers to its role as a key logic and interface component that, in some legacy systems, ran under a DOS-based operating environment (or similar real-time executive), or more accurately, managed the system functions that traditionally ran on a main control processor.

⚙️ Key Specifications and Function

| Feature | Specification/Description |

| Product Type | Drive Main Control Assembly (DMCA) / Processor Interface Board |

| Series/Family | GE Speedtronic Mark V Turbine Control Systems and Industrial Drives (e.g., DC2000) |

| Core Function | Logic and Interface Management. This board serves as a vital interface, linking the main processor (like the UCOM board) to external I/O, logging functions, and the local operator keypad (HMI). It handles crucial logic and data flow necessary for reliable system operation. |

| “DOS Main Control” | The term “DOS” is a legacy reference. While the board doesn’t typically run a full PC operating system, it manages the logic execution and environment of the main control process within the real-time industrial control framework. |

| Firmware Role | The suffix AZZ02A indicates that the board is pre-loaded with a specific firmware/software package, which is the primary difference between this and the DS215DMCAG1AZZ01A variant. The firmware defines the board’s exact operational logic and compatibility. |

| Architecture | It is designed to plug into a dedicated slot within the VME rack of the Mark V system, managing key subsystems like event logging and operator input. |

Part Number Breakdown

- DS215: Indicates the board is a high-integration, firmware-loaded assembly in the Mark V series.

- DMCA: Stands for Drive Main Control Assembly (reflecting its role as a main control interface).

- G1: Specifies the Group 1 revision.

- AZZ02A: Designates the assembly type, revision status, and the specific firmware/software version loaded onto the board.

This module is essential for bridging the gap between the high-level control programming and the real-world I/O and user interface, ensuring fast, reliable interaction within the turbine or drive control system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922