الوصف

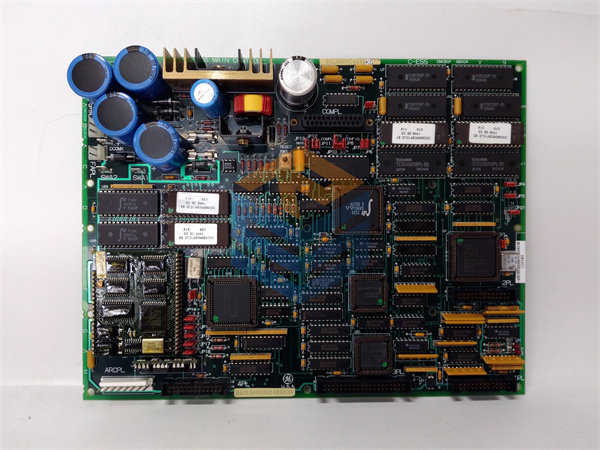

The GE DS215DMCBG1AZZ03A is a specific Printed Circuit Board (PCB) with Firmware that is an integral part of the General Electric (GE) Mark V Speedtronic Turbine Control System.

This board is identified as a “Drive board” within the Mark V series. While the Mark V is now considered an obsolete legacy product line, boards like the DS215DMCBG1AZZ03A are still in use in many power plants globally for the control and management of gas, steam, and sometimes even wind turbines.

The “DS215” prefix suggests it’s a “Drive System” component or a similar type of specialized control board, and the “A” at the end of the part number indicates it’s a later revision or an update to previous versions (e.g., DS200 series boards).

Part One: Optimized SEO Titles

- GE DS215DMCBG1AZZ03A: Mark V Turbine Control Drive Board

- DS215DMCBG1AZZ03A GE: Speedtronic Mark V PCB with Firmware

- GE DS215DMCBG1AZZ03A: Gas & Steam Turbine Control System Component

- Buy DS215DMCBG1AZZ03A: Genuine GE Mark V Control Board

- DS215DMCBG1AZZ03A for Sale: Drive Board for GE Turbines

- GE DS215DMCBG1AZZ03A: Obsolete but Supported Turbine Control PCB

- Mark V Series Board DS215DMCBG1AZZ03A: Critical Control System Part

- DS215DMCBG1AZZ03A GE: High-Density Circuitry for Turbine Automation

- GE DS215DMCBG1AZZ03A: Reliable Control for Industrial Turbines

- DS215DMCBG1AZZ03A PCB: Features FPGAs, EPROMs, and Logic

Part Two: Brief Product Description

The GE DS215DMCBG1AZZ03A is a Drive board with integrated firmware, specifically designed for the GE Mark V Speedtronic Turbine Control System. This printed circuit board is heavily populated with various electronic components, including integrated circuits (such as FPGAs and EPROMs), transistors, and passive components. It plays a critical role in the control and management of gas and steam turbines, handling signal processing, data acquisition, and contributing to the execution of control logic within the Mark V system. While part of a discontinued series, it remains a vital component for maintaining existing Mark V installations.

- Product Type: Printed Circuit Board (PCB) with Firmware

- Manufacturer: General Electric (GE)

- Compatibility: GE Mark V Speedtronic Turbine Control System (DS200 series)

- Primary Function: Drive board for turbine control, signal processing, and data management.

- Key Features: Highly populated with integrated circuits, fuses, jumper switches, LED indicators, and test points.

Part Three: Detailed Product Description

The intricate dance of a gas or steam turbine, converting vast amounts of energy into usable power, is orchestrated by a precise control system. For decades, a cornerstone of this control has been the GE Speedtronic Mark V system. Within this sophisticated architecture, components like the GE DS215DMCBG1AZZ03A printed circuit board act as the nerve center, translating digital commands into the physical actions that keep the turbine operating efficiently and safely. This board, specifically identified as a “Drive board,” is critical for interfacing with and controlling various aspects of the turbine’s operation.

In one power plant, an aging Mark V system experienced a mysterious intermittent fault that was impacting the speed control of a critical gas turbine. After meticulous diagnostics, the issue was traced back to this very component. Even though the Mark V system is considered legacy, the ability to replace and recalibrate a specific “Drive board” like the DS215DMCBG1AZZ03A meant the plant could avoid a costly and time-consuming full control system upgrade. This highlights the enduring value and necessity of understanding and maintaining these older, yet still highly functional, control system components. The complex array of components on the board, from FPGAs to power-regulating elements, is a testament to its critical and multifaceted role.

A Core Component of the Mark V Speedtronic System: The GE DS215DMCBG1AZZ03A is a highly integrated printed circuit board with embedded firmware, designed to function as a “Drive board” within the GE Mark V Speedtronic turbine control system. The Mark V system itself is renowned for its triple redundant architecture (TMR – Triple Modular Redundancy), which ensures extremely high reliability and availability for critical turbine operations. While the exact, granular function of every component on this board is proprietary, its general role as a “Drive board” implies:

- Signal Conversion and Conditioning: It processes and conditions signals from various sensors and transducers (e.g., speed, temperature, pressure, vibration) that are essential for turbine control. This could involve analog-to-digital conversion, filtering, and amplification.

- Actuator Control: It likely generates the control signals for various turbine actuators, such as fuel valves, bypass valves, and other devices that directly influence the turbine’s speed, load, and protective functions. The “Drive” designation strongly suggests it manages output signals for power electronics or specific drives within the turbine system.

- Logic Execution and Data Processing: It contains significant computational power (e.g., oscillating chips, Field Programmable Gate Arrays (FPGAs), EPROM chips for data storage) to execute complex control algorithms and process large amounts of data in real-time, crucial for the precise and rapid response required by turbine control.

- Communication Interface: It communicates with the main Mark V processor boards (e.g., the C, R, and S cores in a TMR system) via internal backplane connections and various cable connectors.

- Self-Diagnostics and Protection: Like most critical industrial control boards, it features diagnostic LEDs and test points (TP) for checking board voltages, aiding in troubleshooting. It also contains fuse components for protection.

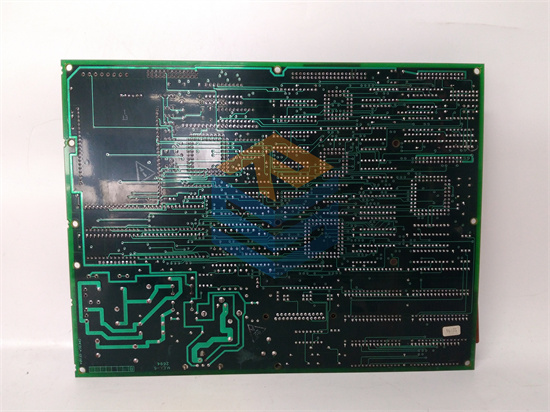

Heavily Populated and Robust Design: The DS215DMCBG1AZZ03A is described as a heavily populated board, featuring:

- Over fifty-five integrated circuits: Including oscillating chips, Field Programmable Gate Arrays (FPGAs) for customizable logic, and EPROM chips for firmware and data storage.

- Passive and Active Components: Resistor network arrays, transistors, capacitors, and diodes.

- Connectivity: Multiple vertical cable connectors (four male, one female), three vertical header connectors, and three stab-on connectors for robust and secure connections within the control system rack.

- Auxiliary Boards: Two smaller auxiliary boards (one vertically mounted, one horizontally mounted) are integrated onto the main PCB, indicating specialized sub-functions or modularity within the board’s design.

- User Adjustability/Diagnostics: Over twenty jumper switches for configuration and a reset switch.

- Protective Coating: The PCB is protected by a chemically applied coating for daily wear and tear protection.

Technical Specifications (General, as precise details are often proprietary; always consult official GE documentation or trusted industrial automation suppliers for specific details):

Key Applications:

The GE DS215DMCBG1AZZ03A is found in critical industrial applications globally:

- Gas Turbine Power Plants: For regulating fuel delivery, combustion control, speed governance, and overall operational sequencing of gas turbines.

- Steam Turbine Power Plants: Controlling steam admission, speed, and load of steam turbines used in power generation.

- Combined Cycle Power Plants: Integrating control across both gas and steam turbine units within a combined cycle setup.

- Industrial Turbine Applications: Used in various industrial processes where turbines provide mechanical drive or process power.

Related Products:

The GE DS215DMCBG1AZZ03A functions as part of a larger Mark V system, alongside:

- Other Mark V PCBs: Including processor boards (like the C, R, S cores), I/O boards, and communication boards that make up the triple modular redundant architecture.

- Mark V Racks/Cabinets: The physical enclosures that house and connect all the Mark V boards.

- Peripherals: Such as operator interfaces, HMI workstations, and data historians that connect to the Mark V system.

- Field Devices: The sensors (thermocouples, pressure transducers, speed sensors) and actuators (fuel valves, hydraulic servo valves) that the Mark V system interfaces with to control the turbine.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922