الوصف

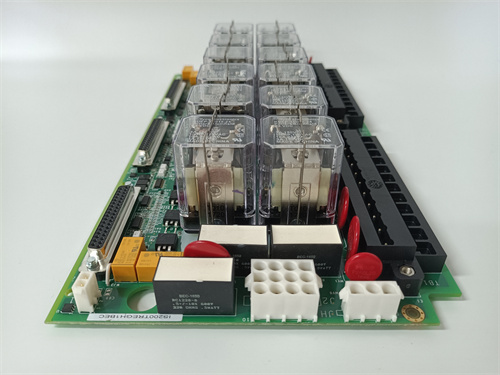

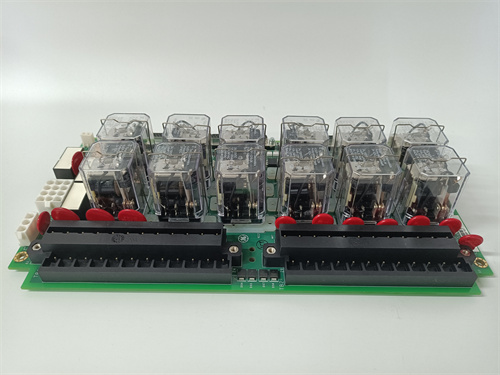

The GE DS215KLDBG1AZZ02A is a specialized and highly critical component within General Electric’s industrial control systems. It is identified as a Key/LED/Display Board, often found in the GE Speedtronic Mark V Turbine Control System and associated drive platforms.1

This module serves as a localized Human-Machine Interface (HMI), providing operators and technicians with immediate visual feedback and a means of local control or configuration.

💡 Key Specifications and Function

| Feature | Specification/Description |

| Product Type | Key/LED/Display Board (KLDB) / Operator Interface Panel |

| Series/Family | GE Speedtronic Mark V Gas and Steam Turbine Control Systems |

| Core Function | Local Monitoring and Control Interface. It provides the local I/O for operator interaction with the turbine/drive control system, separate from the main HMI computer. |

| Display Components | Typically features multiple visual indicators, which can include: * LED Indicators: Numerous LEDs (e.g., 32 total) for status, alarm, and fault indication (e.g., DS1-DS32). * Alphanumeric Displays: Multiple 4-character or 16-segment displays (e.g., 7 or 21 total) to present numerical data and fault codes. |

| Input | Features a keypad or dedicated control points for local operator input, allowing users to navigate menus, acknowledge alarms, or initiate certain sequences. |

| Architecture | It is a highly integrated printed circuit board that plugs into the VME rack or connects to the main controller boards of the Mark V system via a dedicated ribbon cable. |

| Firmware Role | The suffix AZZ02A is crucial, confirming that the board is pre-loaded with a specific firmware/software package necessary to drive its display functions and communicate effectively with the main turbine controllers (R, S, and T). |

| Revision Level | The G1 specifies the Group 1 hardware revision. |

In the Mark V system, the DS215KLDBG1AZZ02A is essential for on-site diagnostics, troubleshooting, and basic operational control, especially during startup or in the event that the primary computer-based HMI is unavailable.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922