الوصف

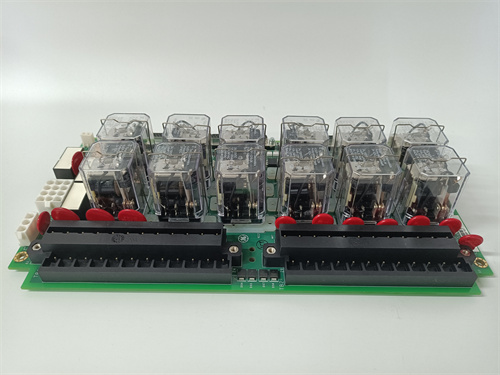

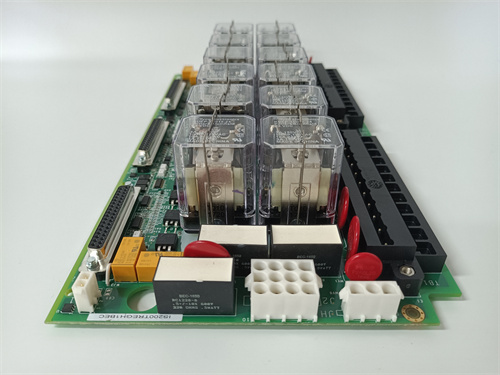

The GE DS215TCQAG1BZZ01A is an Analog I/O Board, often referred to by its functional acronym TCQA, designed for the General Electric Speedtronic Mark V Gas and Steam Turbine Control Systems.

The “Circuit Board with Firmware” description is often used by vendors as this board contains an onboard microprocessor and EPROM modules that store the necessary operational firmware.

💡 Core Function: Analog Signal Processing

The TCQA board serves as the primary interface for analog field signals, performing the crucial task of conditioning, scaling, and transmitting these signals between the turbine sensors and the main control processors.

Its responsibilities include:

- Input Scaling and Conditioning: It reads a large number of analog signals from various terminal boards (like TBQA and TBQC) and scales them for the control system’s processors.

- Signal Types: It handles a wide range of critical inputs and outputs, including:

- LVDT Inputs: Position feedback from hydraulic actuators (e.g., servo valves).

- Thermocouple Inputs: Temperature measurements, including cold junction correction.

- 4-20 mA Inputs/Outputs: Standard industrial current loops for process variables (e.g., fuel flow, pressure).

- Vibration Inputs and Pulse Rate Inputs (from magnetic pick-ups for speed).

- Servo Valve Outputs: Control signals sent to the electro-hydraulic system.

- Communication: It transfers the conditioned data across the 3PL (Data Bus) to other boards in the control core, such as the STCA and TCQE boards, and to the main processors via the IONET.

⚙️ Technical and Hardware Features

- System Series: GE Speedtronic Mark V Turbine Control System (including the LM Series).

- Location: The board is typically installed in the Analog I/O Cores (e.g., R1, R2, and R3) of the Mark V cabinet.

- Configuration: The board’s functionality is configured using both onboard hardware jumpers (e.g., J1-J2 for mA output circuits or J5-J6 for current range selection) and software constants defined in the I/O Configuration Editor.

- Indicators: It features several LEDs to provide visual feedback and diagnostic status to the operator during operation.

- Connectors: It is populated with multiple 34-pin and 40-pin connectors (labeled JA, JB, JD, JE, JG, 3PL, etc.) for ribbon cable connections to terminal boards and other core boards.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922