الوصف

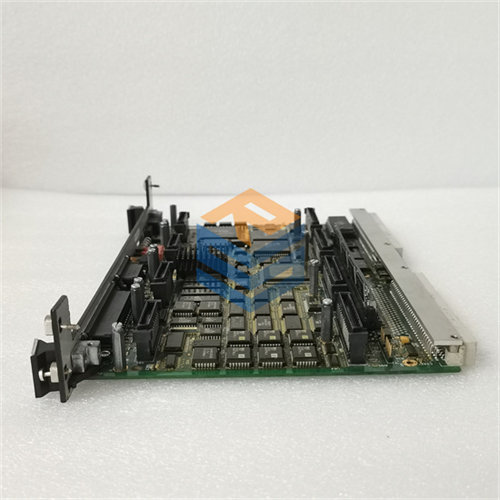

The GE DS215TCQAG1BZZ01A is a specialized Analog I/O Card with firmware, used in the GE Speedtronic Mark V series of gas turbine control systems. It is a critical component for processing and conditioning analog signals from various sensors and terminal boards.

1. Function and Purpose

The primary function of the DS215TCQAG1BZZ01A is to serve as a high-speed interface between the Mark V’s digital control system and the analog world of physical sensors and actuators. It’s often located in the TC2000 C core, a key section of the Mark V control panel. Its key roles include:

- Signal Conversion and Conditioning: It processes a variety of analog signals, including those from RTDs (Resistance Temperature Detectors), 4-20 mA current loops, and other inputs from terminal boards. The board converts these raw analog signals into a digital format that the main control processors can understand and use for control and protection.

- Data Bus Integration: The conditioned signals are then transferred to the main core processors via a dedicated data bus, specifically the 3PL connector. This ensures the main processors receive accurate data in real-time for turbine control and diagnostics.

- Firmware-Driven: The “w/firmware” designation means the board has dedicated, on-board software that defines its functionality. This firmware allows it to manage signal processing and communication independently, reducing the workload on the main processors.

- Advanced Diagnostics: The card includes on-board diagnostics and uses software-implemented fault tolerance (SIFT) to ensure reliability. The redundant TCQA boards can “vote” on a command, and the two-out-of-three majority vote will prevail.

2. Technical and Design Features

The DS215TCQAG1BZZ01A is a robust, industrial-grade circuit board designed for reliability in harsh environments.

- Group 1 Product: The “G1” in the part number indicates that this board belongs to the first grouping of its product family, representing a specific revision with a particular set of features and hardware.

- Connectivity: The board has multiple connectors to facilitate various functions. The 2PL connector distributes power from the system’s power supply. The JHH connector carries 4-20 mA inputs, while the JII connector is specifically for RTD inputs.

- Protection: The board is built with a protective coating to shield its components from environmental factors such as dust, moisture, and mild corrosive elements.

- Redundancy: This board can be used in both Simplex and Triple Modular Redundant (TMR) redundancy applications, which is a key feature of the Mark V system.

A video about a Mark VIe/Mark VIeS I/O card replacement procedure is relevant because it shows the general process of how to replace an I/O card in a modern GE control system, which is similar to the maintenance procedures for the DS215TCQAG1BZZ01A.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922