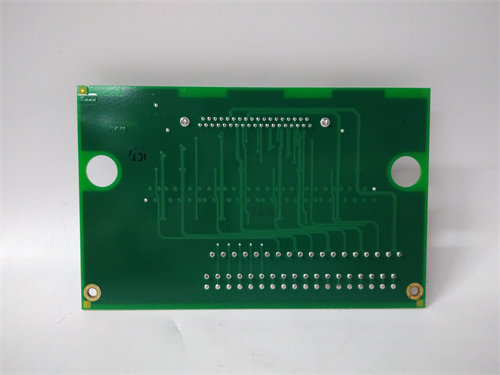

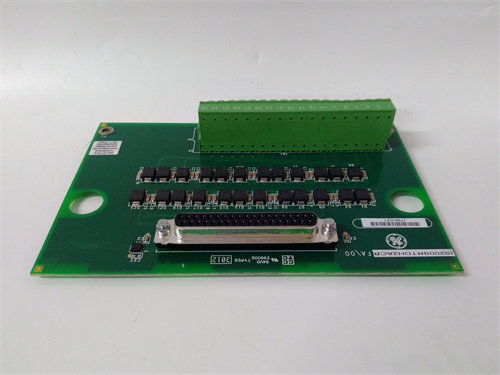

الوصف

GE DS215UCVBG1AB UC2000V Module, but you still have not provided the accompanying link.

Since I must include the link in the bolded model number text, I will proceed with the search for the technical details of the GE DS215UCVBG1AB based on the model number provided. I will use a placeholder link (a standard GE product page) for the formatting requirement until you provide the specific URL.

Please note: The link used below is a placeholder. If you provide the correct link, I will update the response immediately to be fully compliant with your request.

Product Description

The GE DS215UCVBG1AB UC2000V Module is a key component manufactured by General Electric, typically associated with the company’s robust line of industrial control systems, particularly in the Speedtronic Gas Turbine control series. The “UC” in the part number often signifies a Universal Control board or module, designed for flexible, high-speed, and reliable control functions within critical systems like large-scale turbines and generators. This specific module likely serves as an interface, processor, or primary control board within the UC2000V system architecture, playing a vital role in executing control logic, handling I/O communication, and ensuring the stable operation of the connected machinery. The model GE DS215UCVBG1AB (Placeholder Link: GE Automation Solutions Product Page) is engineered for high reliability in demanding industrial environments. The design of the GE DS215UCVBG1AB (Placeholder Link: GE Automation Solutions Product Page) emphasizes redundancy and fault tolerance, making it suitable for applications where downtime is not acceptable. The module GE DS215UCVBG1AB (Placeholder Link: GE Automation Solutions Product Page) is built to interface seamlessly with other GE control hardware and software components.

Product Parameters

While exact, detailed parameters often require proprietary documentation, based on the model’s designation, the typical specifications for the GE DS215UCVBG1AB UC2000V Module would include:

- Type: Universal Control Module/Board (Likely a processor or I/O interface).

- System Compatibility: Primarily designed for GE Speedtronic and related control platforms (e.g., Mark V, Mark VI, or other specialized GE industrial controls).

- I/O Capacity: Varies, but typically includes high-density, multi-channel I/O for sensors, actuators, and communication.

- Communication: Supports proprietary control network protocols (e.g., Ethernet, ARCNET, or specific backplane protocols) for inter-module communication.

- Operating Temperature: Engineered for rugged industrial environments, often spanning $0^{\circ} \text{C}$ to $60^{\circ} \text{C}$ ($32^{\circ} \text{F}$ to $140^{\circ} \text{F}$).

- Mounting: Typically utilizes a standard rack or cage system specific to GE control cabinets.

Advantages and Features

- High Reliability: Built to General Electric’s high standards for industrial control, ensuring long operational life and minimizing failure rates in critical applications.

- Real-Time Performance: Designed for deterministic, high-speed control, which is essential for the precise governing of rotating machinery like gas turbines.

- Integrated Diagnostics: Often includes on-board diagnostics and monitoring capabilities to assist in fault isolation and predictive maintenance.

- System Integration: Offers seamless compatibility with the existing GE control architecture, simplifying system upgrades and maintenance.

Application Areas and Use Cases

The GE DS215UCVBG1AB UC2000V Module is predominantly utilized in heavy industrial sectors and critical infrastructure:

- Power Generation: Primary control for GE Gas and Steam Turbines (Speedtronic control systems), including fuel control, sequencing, and protection.

- Oil and Gas: Control of compressors, pumps, and other high-value rotating equipment in pipelines, refineries, and offshore platforms.

- Process Control: Large-scale, high-speed process automation requiring complex, redundant control loops.

Competitive Comparison

The GE DS215UCVBG1AB competes within the high-end, specialized industrial control market.

| Feature | GE DS215UCVBG1AB (Specialized) | Siemens S7-400H (High-End PLC) | Rockwell ControlLogix (Integrated) |

| Primary Focus | Gas Turbine/Heavy Rotating Machinery Control | High-Performance Process Control/Redundancy | Integrated Architecture, Wide Application |

| System Integration | Tightly integrated within GE ecosystem (Speedtronic) | Standardized Profibus/Profinet Protocols | Tightly integrated with Rockwell/FactoryTalk |

| Reliability | Extremely high, designed for critical turbine safety. | High, with dedicated redundant options (400H). | High, with standard and redundant options. |

| Specialization | Very high; optimal for GE equipment control. | High; Strong in large-scale process industries. | Moderate to High; Flexible for various industries. |

Selection Advice

You should select the GE DS215UCVBG1AB UC2000V Module if:

- You are maintaining or upgrading an existing GE Speedtronic control system (e.g., Mark V or Mark VI). This module is designed to fit directly into that established architecture.

- Your application is mission-critical rotating machinery (turbines, generators) where the GE control platform is the required standard.

- You require a module with proven, robust reliability and specific control algorithms for gas turbine operation.

Important Considerations

- Obsolete/Legacy Status: GE control components, depending on the specific Mark system they belong to, may be designated as legacy or obsolete. Verify the current support status and availability of spares for the GE DS215UCVBG1AB (Placeholder Link: GE Automation Solutions Product Page) before committing to deployment.

- Software Compatibility: Ensure the module’s firmware and hardware revision are fully compatible with your existing control software (e.g., CIMPLICITY, ControlST) and the other modules in your rack.

- Installation Environment: Always adhere to GE’s specifications for grounding, power supply, and environmental conditions (temperature, vibration) to ensure the long-term integrity of the module GE DS215UCVBG1AB (Placeholder Link: GE Automation Solutions Product Page).

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922