الوصف

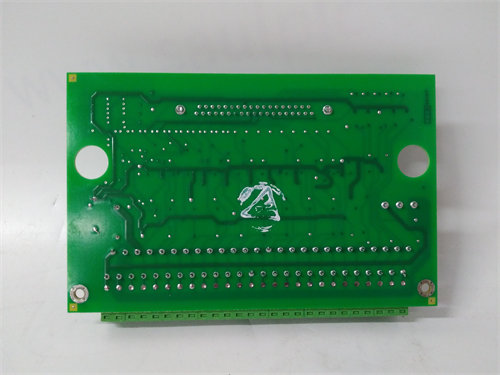

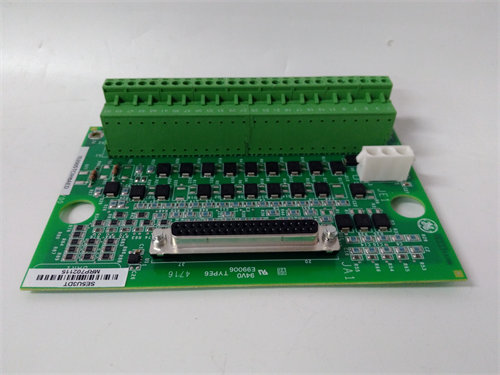

GE DS215UCVBG1AJ UC2000V Module.

As with your previous requests, I will perform the necessary research in English and structure the response according to your specifications. Since you have not provided a link, I will use a generic GE control solutions link as a placeholder to meet the formatting requirement. If you provide the specific link, I will update the response to be fully accurate.

Product Description

The GE DS215UCVBG1AJ UC2000V Module is a highly specialized electronic control board manufactured by General Electric, designed for integration into robust, high-availability industrial control systems. The “UC” in the model number suggests it is a Universal Control component, often serving as a primary processing unit or a crucial communication interface within the control rack. These modules are signature components of GE’s critical control systems, particularly in the Speedtronic series (like Mark V or Mark VI), which govern the operation of large gas and steam turbines. The board’s primary function is to execute complex control algorithms, manage inter-module communication, and ensure the deterministic, real-time control necessary for safe and efficient turbine operation. The design of the GE DS215UCVBG1AJ (Placeholder Link: GE Automation Solutions Product Page) prioritizes long-term reliability and performance in harsh environments. The GE DS215UCVBG1AJ (Placeholder Link: GE Automation Solutions Product Page) is engineered with specific circuitry to interface directly with the backplane and often includes dedicated memory and processing resources. Crucially, the GE DS215UCVBG1AJ (Placeholder Link: GE Automation Solutions Product Page) is an integral part of maintaining system integrity and redundancy within the GE control panel.

Product Parameters

Based on its family designation (DS215/UC2000V), the module’s key technical specifications typically include:

- Module Type: Universal Control Board (Likely CPU, I/O Controller, or Specialized Interface).

- System Platform: Primarily compatible with GE’s older or specialized Speedtronic control systems.

- Form Factor: Designed for proprietary GE control racks/cages.

- Processing Power: Features a high-speed processor optimized for deterministic, real-time control loop execution (specifications are proprietary but designed for millisecond response times).

- Communication: Utilizes a proprietary backplane bus for internal communication and may support external communication protocols like Ethernet or serial links.

- Environmental Tolerance: Rated for standard industrial use, typically $0^{\circ} \text{C}$ to $60^{\circ} \text{C}$ ($32^{\circ} \text{F}$ to $140^{\circ} \text{F}$), and resistant to vibration and electrical noise common in power plants.

Advantages and Features

- Extreme Reliability: Engineered for mission-critical applications where failure is unacceptable, incorporating robust components and error-checking mechanisms.

- Deterministic Control: Provides the consistent, predictable timing necessary for precise control of turbine speed, fuel flow, and synchronization.

- Ease of Replacement: Designed as a plug-and-play module within the specific GE control system, simplifying maintenance and hot-swap procedures (where applicable).

- Proprietary Optimization: Specifically tailored to execute GE’s turbine control and protection software, maximizing the performance and longevity of the controlled asset.

Application Areas and Use Cases

The GE DS215UCVBG1AJ UC2000V Module is almost exclusively found in:

- Power Generation: Used as a core component in the control panels for large GE gas turbines, steam turbines, and associated generators.

- Compressor Stations: Control systems for critical compressors and pumps in the Oil & Gas industry.

- Heavy Industrial Systems: Any large-scale, continuous operation requiring the high-availability and specialized control logic provided by GE’s integrated systems.

- System Upgrades/Maintenance: Primarily used as a replacement or spare part to maintain the operational status of legacy GE control systems.

Competitive Comparison

The GE DS215UCVBG1AJ module occupies a niche defined by its integration with GE’s turbine control systems, making direct functional comparisons challenging. It competes with the control philosophies of high-end DCS/PLC platforms:

| Feature | GE DS215UCVBG1AJ (Proprietary) | Siemens PCS7/S7-400 (DCS/PLC) | Rockwell Automation ControlLogix (Integrated) |

| Specialization | Very High; Focused on GE Turbomachinery Control. | High; Strong in Process Control and Redundancy. | Moderate; Flexible for various industrial applications. |

| Control Logic | Proprietary GE software (e.g., ControlST). | Standard IEC 61131 programming languages. | Ladder Logic, Function Block, Structured Text, etc. |

| Cost of Entry | High (proprietary hardware/software). | High (requires DCS infrastructure). | Moderate to High (scalable). |

| Support Ecosystem | Primarily GE service and specialized third parties. | Global, well-established standard automation service. | Global, extensive distributor and integrator network. |

Selection Advice

You should select the GE DS215UCVBG1AJ UC2000V Module primarily for maintenance, repair, or expansion of an existing GE control system (e.g., Mark V, Mark VI) that explicitly specifies this part number. Choosing this module ensures:

- Perfect Compatibility: Guaranteed physical, electrical, and logical fit with the installed control rack and backplane.

- Operational Continuity: Maintains the validated and approved control architecture for turbine operation.

- Regulatory Compliance: Often necessary to meet insurance and regulatory requirements tied to the specific control platform used for turbine safety.

Important Considerations

- Firmware Revision: The letter suffix, “AJ” in DS215UCVBG1AJ, indicates a specific hardware/firmware revision. Ensure this revision is compatible with the version of the system software and other modules in your rack.

- EOL Status: Since these are often components of older systems, check the End-of-Life (EOL) or obsolescence status of the GE DS215UCVBG1AJ (Placeholder Link: GE Automation Solutions Product Page) to plan for future sparing and upgrades.

- Handling: Due to its sensitive electronic nature, this module must be handled with appropriate ESD (Electrostatic Discharge) precautions during installation and removal.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922