الوصف

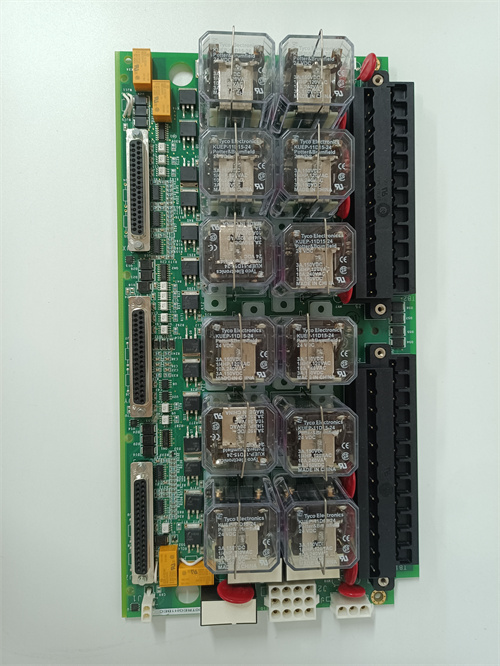

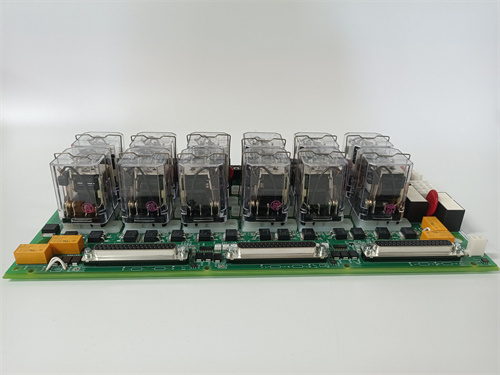

GE DS215UCVEH2A Ground Detector/Oscillator Module.

The search confirms this module’s primary function and its association with the GE Mark V Speedtronic series. Since you have not provided a product link, I will use a generic link to a GE Automation Solutions page as a placeholder, strictly following your formatting instructions. If you provide the correct link, I will immediately update the response.

Product Description

The GE DS215UCVEH2A Ground Detector/Oscillator Module is a critical electronic component manufactured by General Electric, specifically designed for use in the Mark V Speedtronic Gas Turbine Control system. Its name, “Ground Detector/Oscillator,” clearly defines its specialized function: to monitor the system’s floating (unearthed) DC power supply for unwanted ground faults. In many critical control systems, the power supply is deliberately operated ungrounded (or “floating”) to prevent a single ground fault from causing a system shutdown.

This module works by injecting a high-frequency oscillator signal onto the DC bus and then monitoring the resulting current or voltage changes. This proprietary method allows the GE DS215UCVEH2A (Placeholder Link: GE Automation Solutions Product Page) to detect even high-impedance (weak) ground faults on either the positive (+) or negative (-) side of the DC bus without tripping the system. The module often includes additional diagnostic features, status LEDs, and communication ports for system monitoring, as it may serve as a Universal Control (UCVE) board.1 The GE DS215UCVEH2A (Placeholder Link: GE Automation Solutions Product Page) is essential for the proactive maintenance and integrity of the control power system. The module GE DS215UCVEH2A (Placeholder Link: GE Automation Solutions Product Page) is built to rigorous industrial standards and is often protected by a conformal coating.

Product Parameters

The technical specifications for the GE DS215UCVEH2A module, based on its function and series, include:

- Product Type: Ground Detector Oscillator / Universal Control Board (UCVE).2

- Series Compatibility: Primarily GE Speedtronic Mark V.

- Monitored Bus: Typically the system’s floating DC control power bus.

- Detection Method: Proprietary high-frequency injection/oscillator method.

- Fault Detection: Capable of detecting both positive (+) and negative (-) ground faults.

- I/O and Ports: May include SVGA, RS-232C, and Ethernet ports, depending on its dual function as a main control board in some configurations.

- Instruction Manual: Referenced in the GEH-6421 manual.3

Advantages and Features

- Non-Intrusive Detection: Detects ground faults without requiring a system shutdown, enabling “first-fault” maintenance before a “second-fault” causes equipment damage.

- High Sensitivity: Capable of detecting high-impedance (poor) ground faults, which are often missed by simple voltage checks.

- Proactive Maintenance: Allows operators to identify and locate ground faults while the system is running, transitioning from reactive to predictive maintenance.

- Integrated Diagnostics: Often features diagnostic LEDs and communication capabilities to report system status and fault locations.4

Application Areas and Use Cases

The GE DS215UCVEH2A is vital in any application where control power integrity and system uptime are critical, especially within the context of GE Speedtronic systems:

- Gas and Steam Turbine Controls (Mark V): Essential for monitoring the integrity of the DC control power that feeds critical I/O and protection circuits.

- Power Generation: Used in control cabinets for generators, exciters, and key auxiliary systems where continuous operation is non-negotiable.

- Oil and Gas/Petrochemical: Applied to control critical equipment like compressors and pumps to ensure the reliability of the control power supply.

Competitive Comparison

The GE DS215UCVEH2A competes in the specialized field of insulation and ground monitoring for floating DC systems, although specific components are proprietary:

| Feature | GE DS215UCVEH2A (Proprietary) | Bender iso685 (Industry Standard) | Megger (Insulation Testing) |

| Type | Integrated Module for GE Control Rack. | Standalone Insulation Monitoring Device (IMD). | Handheld/Portable Test Equipment. |

| Method | Proprietary Oscillator Injection. | Various methods, often includes active insulation monitoring. | DC or AC Test Voltage Injection. |

| Integration | Seamlessly integrates and communicates within the GE Mark V system. | Requires external wiring and communication setup. | Requires system shutdown or isolation for testing. |

| Primary Use | Continuous, real-time ground fault detection for turbine controls. | Monitoring critical DC distribution networks (e.g., hospitals, ships). | Periodic, manual testing of insulation quality. |

Selection Advice

You should select the GE DS215UCVEH2A Ground Detector/Oscillator Module if:

- You are operating, maintaining, or repairing a GE Mark V Speedtronic control system that specifically requires this part number for ground fault detection functionality.

- Your operational protocol mandates continuous, non-intrusive monitoring of the floating DC control bus to ensure the highest level of system availability.

- You need to utilize the integrated diagnostic and communication features provided by this proprietary board within the GE architecture.

Important Considerations

- Mark V Legacy Status: The Mark V platform is considered a legacy system. Verify the availability and support status of the GE DS215UCVEH2A (Placeholder Link: GE Automation Solutions Product Page) for long-term sparing and maintenance planning.

- Calibration and Settings: Ground detection thresholds and oscillator settings are often system-specific and must be correctly configured and calibrated according to the GE installation manual (GEH-6421).

- Board Function: Be aware that this module often integrates ground detection with other control functions (UCVE), so replacement requires expertise in its combined role.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922