الوصف

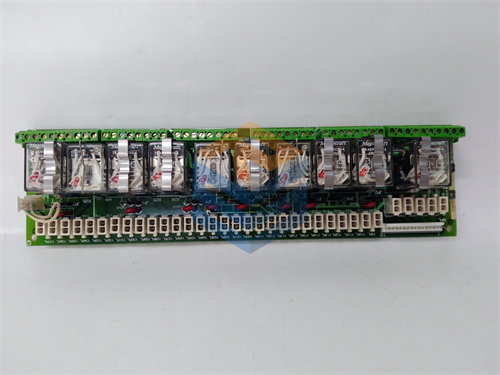

GE DS3800NEVA Early Valve Actuator Card

The GE DS3800NEVA is an Early Valve Actuator Card used in the GE Speedtronic Mark IV series of turbine and generator control systems. It is a legacy component, no longer in production, and is primarily found on the surplus and refurbished markets for the maintenance and repair of older systems.

Function and Purpose

The primary function of the DS3800NEVA is to control the position of a turbine’s valves, particularly during the early stages of operation, such as startup. It acts as a crucial interface between the digital control system and the physical valve actuators. Its key roles include:

- Signal Conversion: It receives a digital command from the main processors and converts it into the analog signal needed to operate the valve actuator.

- Precise Control: The card ensures that the valve’s position is precisely controlled, which is essential for managing fuel flow and steam input to the turbine during critical phases like ignition and speed-up.

- Feedback Loop: It processes feedback from sensors that monitor the valve’s actual position, creating a closed-loop control system. This allows the Mark IV to constantly monitor and correct the valve’s position, ensuring it matches the commanded value.

- Protection: It includes safeguards to prevent the valve from moving to an unsafe position in the event of a system fault.

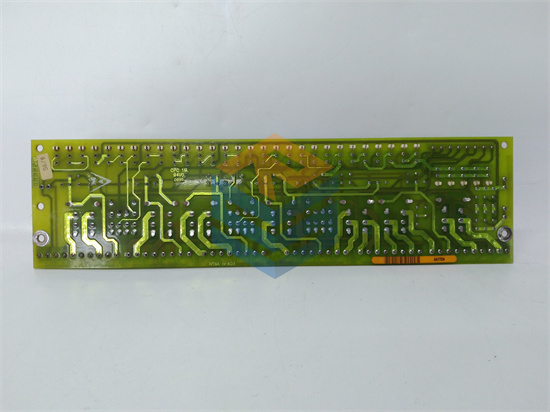

Technical and Design Features

The DS3800NEVA is a robust, industrial-grade circuit board designed to operate in a demanding environment.

- Legacy Part: The “DS3800” prefix indicates that it belongs to the legacy Mark IV series, a pioneering control system for gas and steam turbines in the late 1980s.

- Connectors: The board features two 34-pin connectors and a 20-pin connector, allowing it to interface with other boards and system components in the control rack.

- Jumpers and Trimmers: It is equipped with jumpers and trimmer resistors that allow technicians to configure its operational settings and fine-tune the valve’s control loop for a specific application.

- Status Indicator: It includes a red LED that lights up to indicate a fault or a specific operational status, aiding in troubleshooting.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922