الوصف

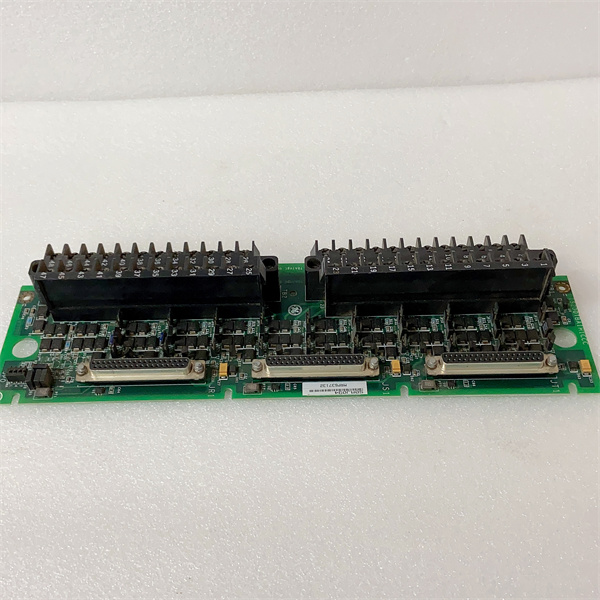

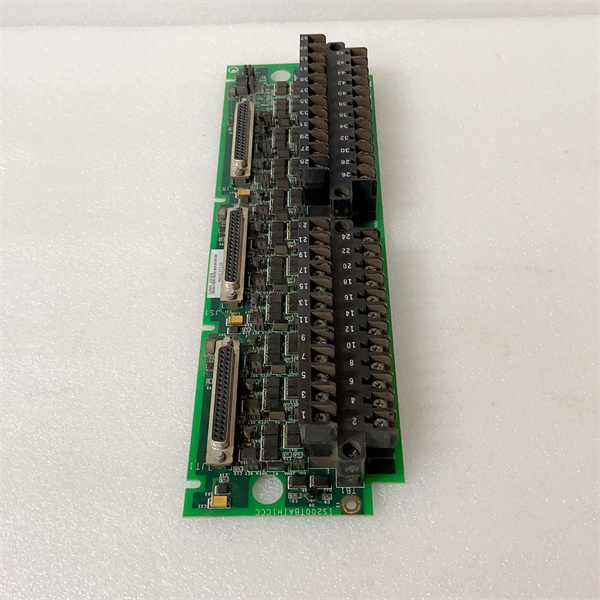

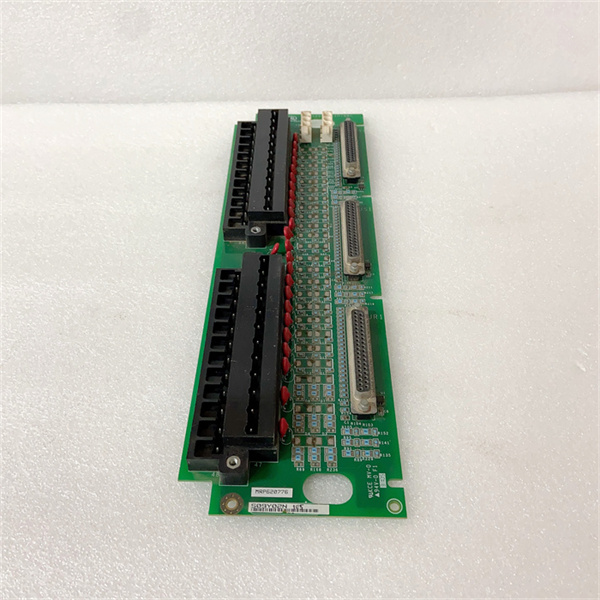

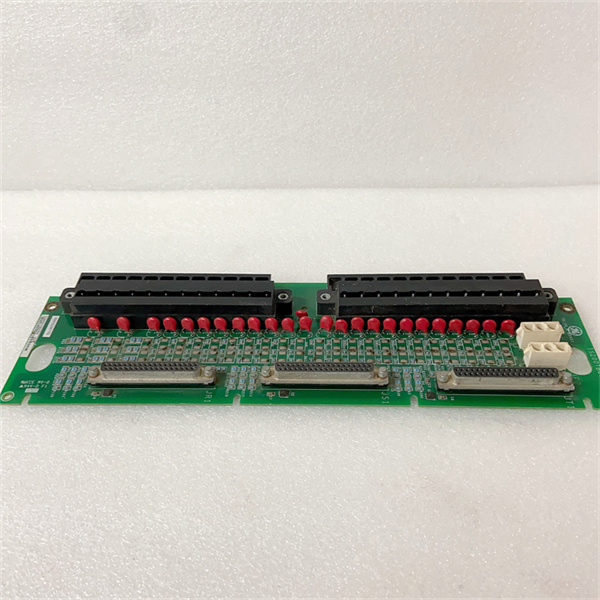

GE DS3820SMTU MKIV, Analog I/O Module

The GE DS3820SMTU is an Analog I/O Module for the Mark IV Speedtronic turbine control system. This highly versatile module serves as the primary interface between the digital controller and a variety of analog field devices, handling both incoming sensor data and outgoing control signals.

Technical Breakdown 🧠

This module is a core component for continuous monitoring and modulation in the control system.

- Analog Input (AI) Function: The module accepts continuous, variable signals from analog sensors, such as pressure transmitters, level sensors, or flow meters. It converts these incoming signals—typically in a range like 4-20mA or 0-10V—into digital values that the main turbine control processor can read, interpret, and use for logic and control.

- Analog Output (AO) Function: It also receives digital commands from the processor and converts them into continuous analog signals. These signals are then sent to modulating devices, such as electro-pneumatic converters, to precisely position a valve or control a variable-speed drive. This allows the system to fine-tune a process rather than simply turning it on or off.

- Signal Conditioning: The

DS3820SMTUprovides critical signal conditioning and electrical isolation. It filters out electrical noise and protects the sensitive control electronics from the high-voltage or high-current signals coming from the field. This ensures the integrity and accuracy of both the input and output signals.

Applications 🏭

The DS3820SMTU is a fundamental component in Mark IV control panels for:

- Closed-Loop Control: Used to create closed-loop control systems for turbine speed, fuel flow, and other critical parameters.

- Proportional Control: Provides the necessary output signals to proportionally control modulating valves.

- Continuous Monitoring: Gathers continuous process data from a wide range of analog field instruments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922