الوصف

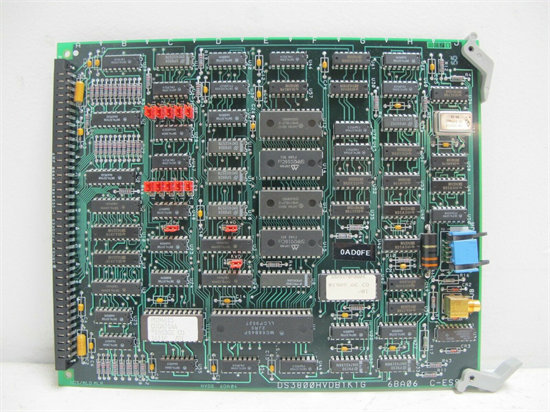

The GE DS3820SMTV is an Analog I/O Module for the Mark IV Speedtronic turbine control system. It provides a versatile interface for processing a variety of analog signals, including both sensor inputs and control outputs, essential for the precise monitoring and operation of a turbine. The V in the part number indicates a specific hardware revision.

Technical Breakdown 🧠

This module is a critical link between the physical world of analog devices and the digital control logic of the Mark IV system.

- Versatile Analog Interface: The

DS3820SMTVis designed to handle a mix of analog signals. It receives inputs from various field sensors, such as pressure transmitters, temperature sensors (thermocouples), and linear position transmitters (LVDTs). It also generates analog outputs to control devices like hydraulic servo valves, which regulate fuel flow or actuator position. - Signal Conditioning: The board performs crucial signal conditioning to ensure data integrity. This includes converting incoming analog signals to a digital format (A/D conversion) for the main processor to use and converting digital commands from the processor into precise analog signals (D/A conversion) for controlling field devices.

- Multiplexing Functionality: The “SMT” in the part number indicates a multiplexing function. This means the board can handle a greater number of signals than would be possible with a dedicated channel for each. It cycles through the connected analog signals, converting them one by one, and sends the data to the main processor.

- System Integration: As a core I/O component of the Mark IV system, this module connects to the main control processor via a backplane. It acts as the bridge that allows the control system to accurately read physical parameters and execute fine-tuned control actions in real-time.

Applications 🏭

The DS3820SMTV is used in Mark IV turbine control systems to:

- Control Analog Devices: Provides precise analog output signals to actuators like servo valves for fuel and steam control.

- Monitor Critical Parameters: Reads and conditions signals from various sensors for temperature, pressure, flow, and position.

- Enable High-Density I/O: The multiplexing design allows for a large number of analog points to be handled by a single module.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922