الوصف

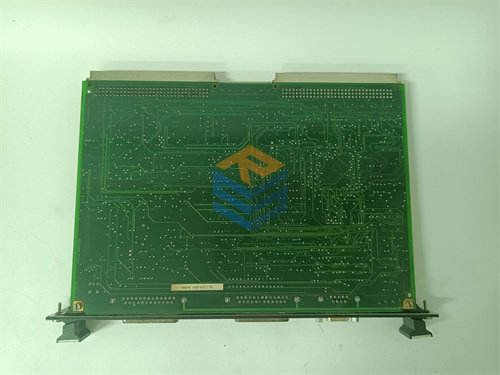

The GE DS3880TIMC is a Thermocouple Isolation Module for the Mark IV Speedtronic turbine control system. Its primary function is to safely and accurately process millivolt signals from thermocouples, providing electrical isolation and signal conditioning. The “C-Coat” designation indicates that it has a Conformal Coating for protection against harsh industrial environments.

Technical Breakdown 🧠

This module is a core component for temperature monitoring and control, providing both accuracy and safety.

- Thermocouple Signal Processing: The

DS3880TIMCis a highly sensitive input board capable of accurately measuring the minute voltage signals generated by thermocouples. It contains the necessary circuitry to amplify, filter, and convert these analog signals into a usable digital format for the main processor. - Cold Junction Compensation (CJC): For accurate temperature measurement, the module performs cold junction compensation. A thermocouple’s output is based on the temperature difference between its hot (measurement) junction and its cold (reference) junction. The

TIMCcard automatically measures the temperature of its own terminals and adjusts the reading to provide a true, absolute temperature measurement. - Electrical Isolation: The most crucial function is electrical isolation. The module electrically separates the thermocouple’s wiring from the control system’s sensitive internal electronics. This prevents ground loops, high-voltage transients, or electrical noise from the field from damaging the control system.

- Conformal Coating (C-Coat): The presence of a conformal coating is a vital protective feature. This thin, polymeric film is applied to the circuit board to act as a barrier against moisture, dust, chemical contaminants, and corrosive gases. This coating significantly enhances the card’s long-term reliability in demanding power generation environments.

Applications 🏭

The DS3880TIMC is a fundamental component in Mark IV control panels for:

- High-Temperature Monitoring: Accurately measuring critical temperatures in combustion chambers, exhaust stacks, and bearing pads.

- Safety and Protection: Providing clean, reliable data for over-temperature alarms and safety shutdown logic.

- Process Control: Supplying accurate temperature readings for precise control of turbine operations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922