الوصف

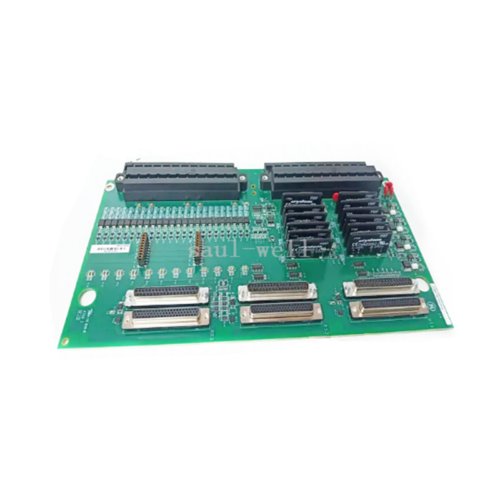

The GE DS4815DTDA is a Data Acquisition System (DAS) Memory Module for the Mark V Speedtronic turbine control system. It is a specialized card that serves as the dedicated memory for the Data Acquisition System, responsible for storing critical operational data, event logs, and historical trends for diagnostic and analysis purposes.

Technical Breakdown 🧠

This module is a crucial component for gathering and storing the operational history of the turbine.

- DAS Function: The Data Acquisition System collects a wide array of data from the turbine’s sensors and control loops. The

DS4815DTDAacts as a high-capacity memory repository for this data. It works in conjunction with the main processors to record parameters like temperatures, pressures, vibration levels, and valve positions at high speed. - High-Speed Logging: The module is designed for high-speed data logging, which is essential for capturing events leading up to a turbine trip or fault. By storing data in a first-in, first-out (FIFO) buffer, engineers can later analyze the “sequence of events” to diagnose the root cause of an issue.

- System Integration: The

DTDAmodule plugs into the Mark V backplane and communicates with the main processors and the operator interface. It provides the data that is displayed in real-time on the HMI and that is archived in the control system for later retrieval by engineers.

Applications 🏭

The DS4815DTDA is a key component in Mark V control panels for:

- Post-Trip Analysis: Providing the data necessary to analyze the events leading to a turbine shutdown, aiding in root cause analysis.

- Historical Trending: Storing historical data for long-term trending of turbine performance, which is crucial for predictive maintenance.

- System Diagnostics: Furnishing the information required for a comprehensive diagnostic review of the turbine’s health and operational history.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922